Pöttinger’s new TOP 342, TOP 382, TOP 422 and TOP 462 single-rotor rakes, with working widths of 3.40m to 4.60m, now include the latest technical developments from the company’s larger rake models.

TOP rakes are especially noticeable for their short headstock. This brings the centre of gravity closer to the tractor. The heart-shaped pivot pin ensures the machine is in the centre position when it’s raised. The vertical point of rotation reliably prevents under-running when working downhill. A slotted hole enables operation with a Multitast wheel and rigid top linkage. Pöttinger implemented this feature during development to deliver the best ground tracking.

A practical PTO shaft holder and ergonomic hose tidy make coupling and uncoupling a great deal easier. A transport interlock flap ensures the unit can be driven safely on the road.

The double-acting shock absorbing struts on both sides ensure the machine is always centred. This is especially important on slopes. Even at high working speeds, these struts ensure that the rake runs very smoothly. The TOP is also stabilised during road transport.

Multitast, the proven Pöttinger jockey wheel system, ensures optimum ground tracking for ideal protection of the sward and forage. The jockey wheel can be shifted independently forward or further back and can be mounted on the left or right. Perfect ground tracking is supported by the tandem axles.

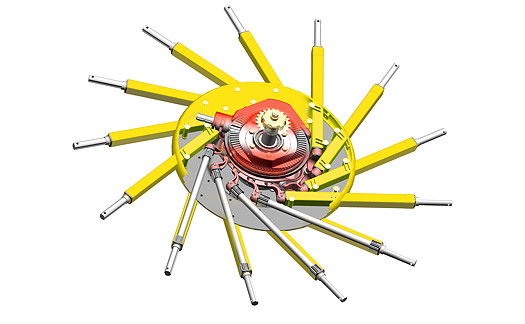

The new Toptech Plus rotor units combine a proven system with innovative technology. On the TOP 422 and 462, Pöttinger offers the largest cam track diameter of 420mm and a tine arm bearing spacing of 600mm. The two smaller TOP 342 and 382 models feature a cam track diameter of 350mm. The large diameter and a cam track without steep inclines provide the tine arms with maximum strength and minimum stress on the arm bearings. The cam track can be greased ergonomically from above. The grease-filled rotor units are sealed and maintenance-free. The tine arms are easy to replace using just two bolts. The control shaft plus cam roller can simply be removed from the rotor casing.

The tines are directed straight at the ground under the tine support, without any need for a steep offset angle. Due to the resistance of the forage, they’re pressed back slightly but don’t rise upwards. They don’t need to be set too deeply to produce tidy work, limiting the stress on the cam track and cam rollers as a result.

Featuring a shaped support disc, the tine mounting provides a secure connection. The outer pairs of tines are slightly shorter so that they do not contact the full volume of forage and the load is lower. The three inner dual tines are used for precision work. The unique tine security system is bolted securely to the tine arm tube by the two outer bolts.

The working height can be adjusted conveniently from the standing position using a hand crank. The swath curtains can easily be adjusted to match the quantity of forage and the desired width of the swath. Raising the swath curtain is effortless. Thanks to large springs, the swath curtain can be folded in and out of the transport position without strain. Hydraulic swath curtain folding is also available as an option.

With the swath curtain raised, the smaller TOP 342 and TOP 382 models achieve a transport width of less than 3m without removing tine arms. All tine arms can be quickly removed if required. Simply pull out the retention clips, remove the tine arms and slot them into the holders. The tines are stowed away tidily and secured in place by linch pins.

Safety is a priority, which is why warning signs and lighting are standard equipment on these new rakes.

For more information visit: www.poettinger.at.