Amazone now offers a special seven-year manufacturer guarantee against rusting through on its ZA-V and ZA-TS mounted fertiliser spreaders and ZG-TS trailed fertiliser spreader.

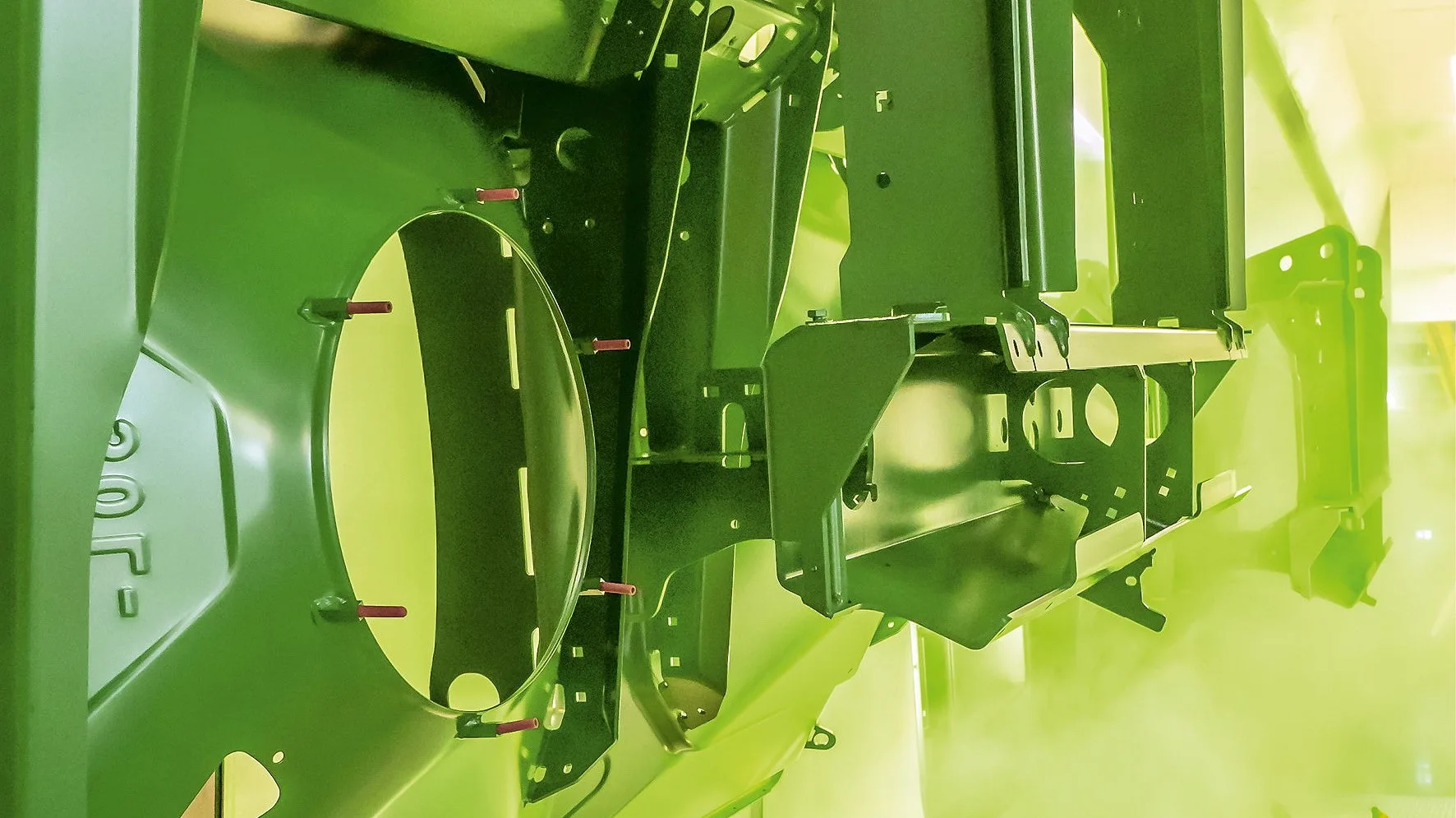

The move follows the introduction of a new premium painting process for these models that’s been used since the 2022 model year. This involves a cathodic dip painting process (known as KTL) for priming to give the best possible protection even on the internal surfaces of tubes. A powder coating then provides an extra-thick coat of paint for increased protection against mechanical knocks and bangs, as well as giving the fertiliser spreader a high-quality visual appearance.

The premium painting is carried out in four main steps. In the first, the carrier material is prepared for painting in 14 processing stages. This includes, for example, multiple etching and degreasing operations.

The fertiliser spreaders are then subject to zinc phosphating in the second step, in order to prevent the formation of rust as effectively as possible, while the third step includes the thick-layer KTL cathodic dip-paint process.

Finally, in the fourth step, the fertiliser spreaders receive their powder coating. The application of a particularly thick powder coating gives the spreaders even better protection against knocks, and provides double corrosion protection as a result of a stove-baking process.