New Holland has taken a further step in its Clean Energy journey by unveiling the T7 Methane Power LNG (liquefied natural gas) pre-production prototype tractor.

The LNG T7 is expected to have twice the autonomy of the brand’s existing CNG (compressed natural gas) T6 Methane Power tractor as it represents a fourfold increase in fuel capacity for the much larger tractor.

LNG is facilitator for the expansion of CNH Industrial’s broader future natural gas portfolio, particularly towards larger and heavier agricultural equipment, as well as construction equipment.

The T7 Methane Power LNG pre-production prototype offers unparalleled performance for an alternative-fuel tractor. With its 270hp, it delivers the same power and torque as a diesel tractor while delivering autonomy without the need for any extra tanks. It’s also more sustainable, being better than carbon neutral when powered by liquefied biomethane sourced from livestock manure/slurry.

The tractor has a six-cylinder FPT Industrial Nef engine that meets the EU Stage V emissions standard with a single three-way catalytic converter and no need for AdBlue. It also features New Holland’s 50km/hr AutoCommand CVT transmission, and the prototype has a maximum oil flow of 170 lit/min and a rear lift capacity of 10,464kg.

Developed by CNH Industrial’s in-house design team, the new tractor is said to be ahead of its time, with a new “Clean Blue” colour accenting sustainable alternative fuels. The all-new exterior features fit with the brand’s new signature design style, which can be seen in the reimagined bonnet with the illuminated New Holland iconic leaf. The exterior is completed by powerful LED taillights with incorporated signature leaf, a C-Pillar illuminated leaf and gloss black wheels with custom Clean Blue accents.

The cab incorporates a full-length skydome roof for enhanced visibility and greater sense of space. The innovative SideWinder Ultra armrest, new larger IntelliView 12 touchscreen and the CentreView fixed hub steering wheel-mounted display make work intuitive – while the ergonomically shaped seats in leather and Alcantara with contrasting stripe and embroidered logo, look sporty as well as being comfortable.

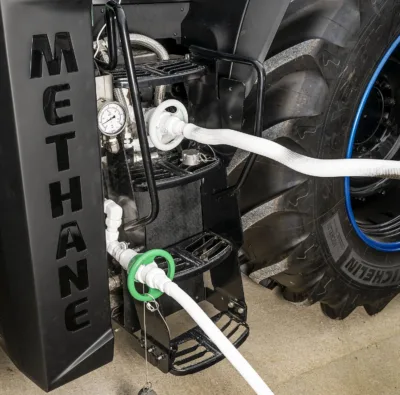

The patented active temperature-controlled fuel system developed for this pre-production prototype incorporates a stainless-steel cryogenic tank that’s expertly molded to match its diesel counterparts, maximising space and effectively storing LNG within a working tractor. The system has a self-supporting vacuum space that insulates the fuel within and reduces the tank’s thickness. Refueling is as easy as that of a diesel tractor. Once out in the field, the tanks’ active temperature control ensures that the engine runs smoothly.

Equipped with New Holland’s latest precision technology – PLM Intelligence – ththe T7 LNG prototype, just like New Holland’s full production fleet, enables the farmer to easily command cutting-edge guidance programs, analyse all field data and stay wirelessly connected with both the field below and key locations across the farm. These important features result in a further boost to productivity and sustainability, allowing customers total control of their operations and the power to make data-driven decisions.

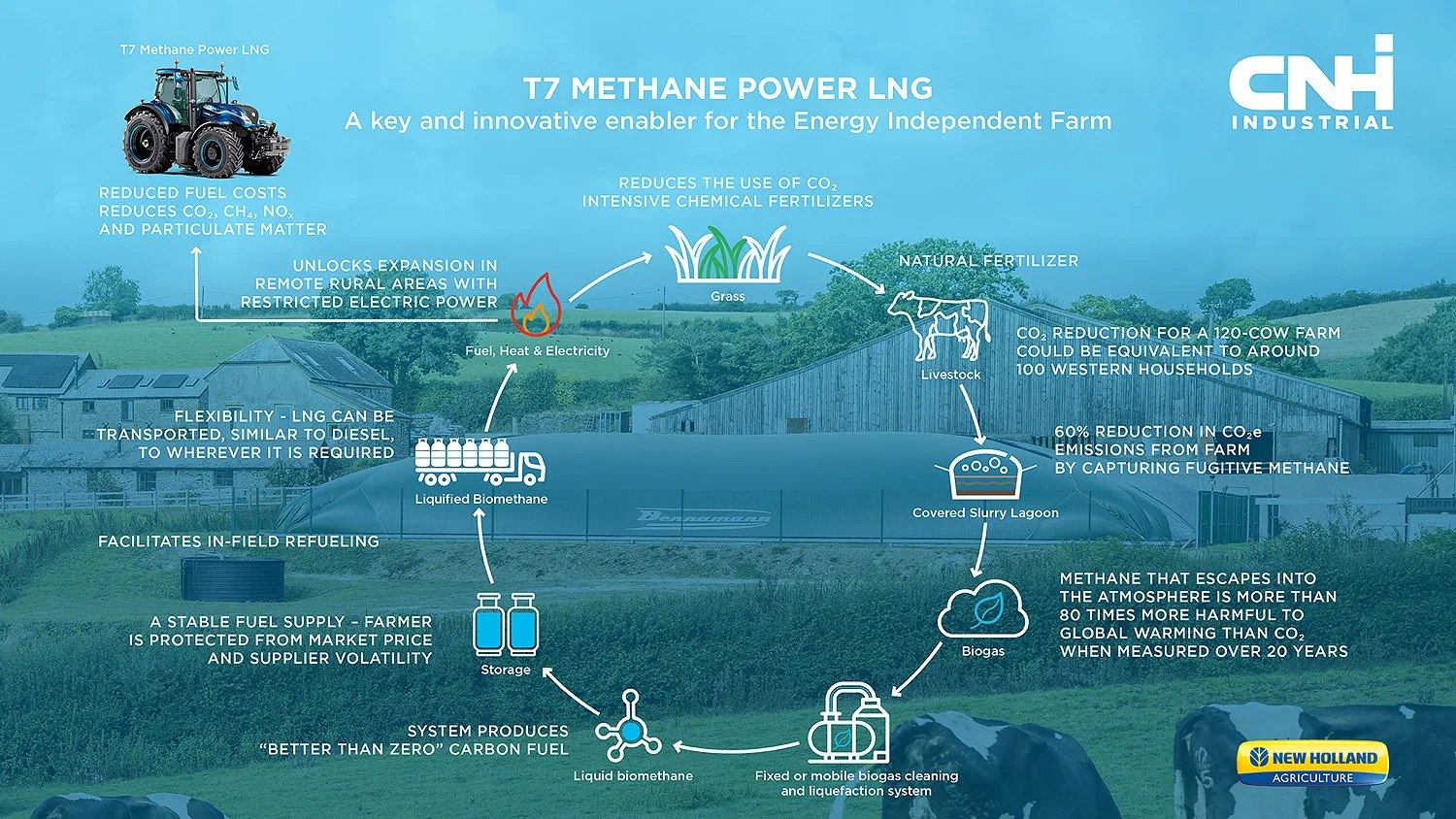

CNH has partnered with Bennamann, a UK-based expert in solutions to capture and repurpose fugitive methane emissions for energy use. The companies have been working together since March 2021 when the Italian-owned industrial giant acquired a minority stake in Bennamann Ltd.

Bennamann’s multi-patented approach prevents methane from entering the atmosphere (methane is more than 80 times more harmful to global warming than CO2 when measured over 20 years) by ultimately converting it into liquefied fugitive methane (LFM) for use as a better-than-zero-carbon biofuel.

The solution can significantly reduce the carbon footprint of an average dairy farm by preventing the direct emission of methane from slurry lagoons and tanks, as well as providing a range of additional benefits. These include reducing the use of CO2 intensive chemical fertilisers, the displacement of fossil fuel use in tractors, electricity generation and heat provision, and a reduction in the need for slurry spreading.

The system empoys a tried-and-tested energy independent sustainable farm system that sees collected livestock manure transferred to a covered slurry lagoon or tank, where the emitted fugitive methane (alongside other polluting gases) is captured and subsequently being purified and converted into liquefied methane using a processing unit. A liquification unit can simply be bolted on to an existing CNG processing unit for further flexibility – ideal for farms which already produce their own biomethane.

Bennamann’s patented non-venting cryogenic storage tanks keep the methane as a liquid at -162C, producing a new source of clean power for the T7 Methane Power LNG tractor. Furthermore, this technology enables LNG to be transported, similar to diesel, to wherever it’s required, meaning farms that don’t have the ability to produce LNG on-site can still benefit from its advantages, as well as enabling flexible in-field refueling during intense operational windows.

When this prototype tractor is integrated within Bennamann’s on-farm liquid fugitive biomethane production process, it’s possible for an operation’s overall carbon footprint to be “better than zero”. The tractor’s surrounding environment also benefits from a significant reduction in drive-by noise levels, making it perfect for tasks near livestock or in urban areas.

The combined expertise and resources of CNH and Bennamann is claimed to enable farmers everywhere to fully integrate this scalable and affordable energy independent system on their farms. It also provides new opportunities and revenue streams to monetise or repurpose their waste. These include: fuel production at a stable cost; sale of excess biomethane on the open market; generation of 100 per cent natural fertiliser; and conversion of excess methane into electricity for export to a grid or local use.

The opportunity for electricity generation is key – this can be used to run electric vehicles (future agricultural machines alongside existing cars and vans) as well as powering the farm, which in remote rural areas, with restricted electric power, could unlock future expansion.