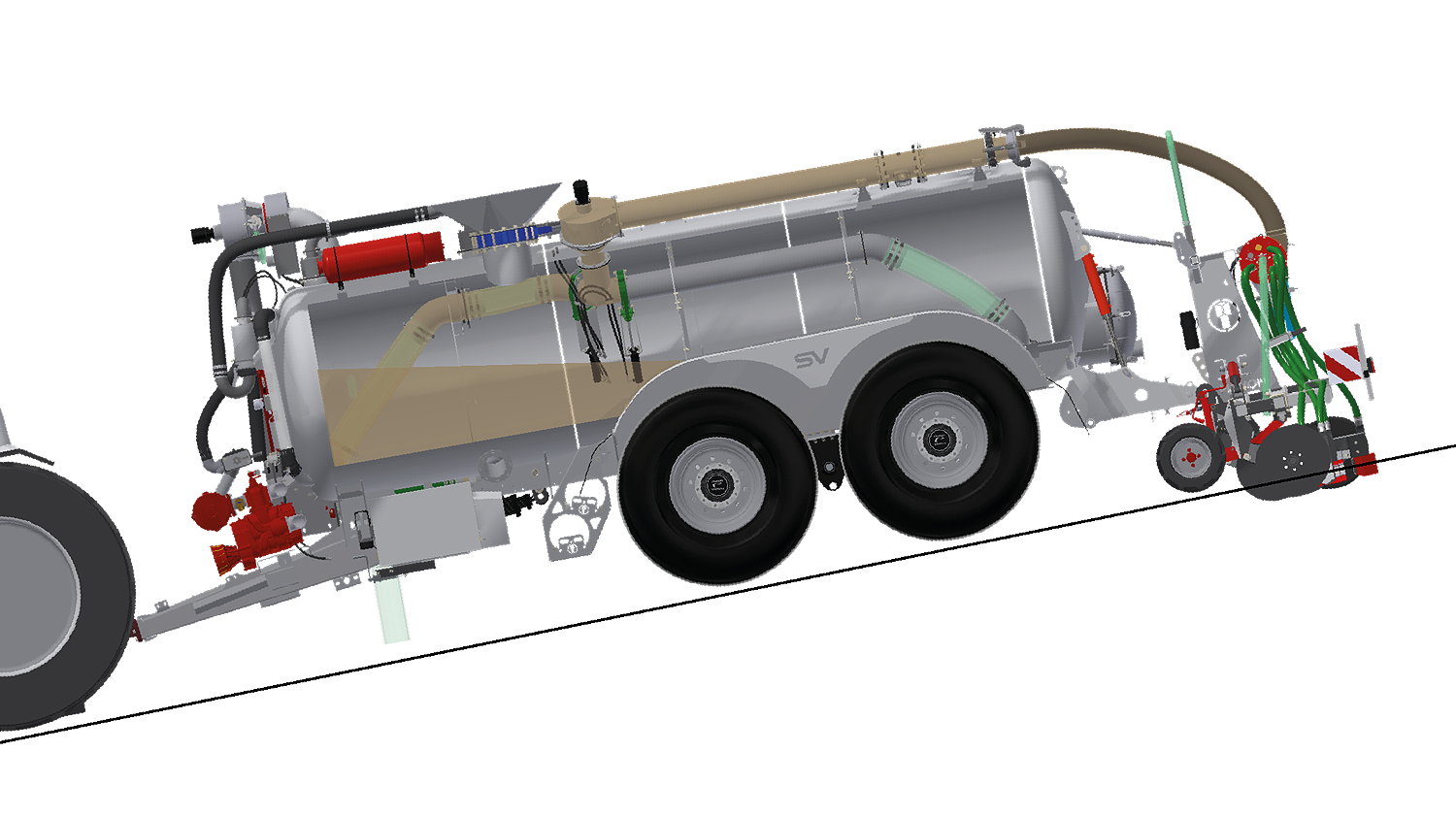

Denmark’s Samson Group has developed the new Alta double unloading system to optimise uphill and downhill slurry applications from its Pichon SV tanker series.

Spreading on hilly terrain is traditionally not easy to control, but the Alta system makes complete uphill and downhill tank unloading a reality. It operates via both a front unloading pipe (downhill emptying) and rear unloading pipe (uphill emptying). The pipes are selected via two immersed hydraulic valves that are controlled manually from the in-cab iControl 7S terminal.

The Alta system completes the most demanding spreading tasks. It’s compatible with the upper unloading pipe linked to the flow regulation valve and turbo feeder. It prevents system failure, ensuring an even and consistent spread. It also makes better use of organic fertilisers in hilly terrain or mountain regions.

From spring 2023 the Alta system will be developed further, with the tanks on Pichon’s SV slurry tankers being fitted with an inclinometer to provide an incline reading in real time. This information will be sent to the in-cab iControl 7S terminal to automatically select the front or rear unloading pipe with no operator input required.

The aim is to reduce the driver’s workload and to make it easier for them to drive in emptying mode.

[embedyt] https://www.youtube.com/watch?v=z61VRv6SRz4[/embedyt]