Quicke has released a new range of Silocut front-loader attachments to increase efficiency and safety when managing silage. The offering comes with various options to ensure it matches users’ requirements.

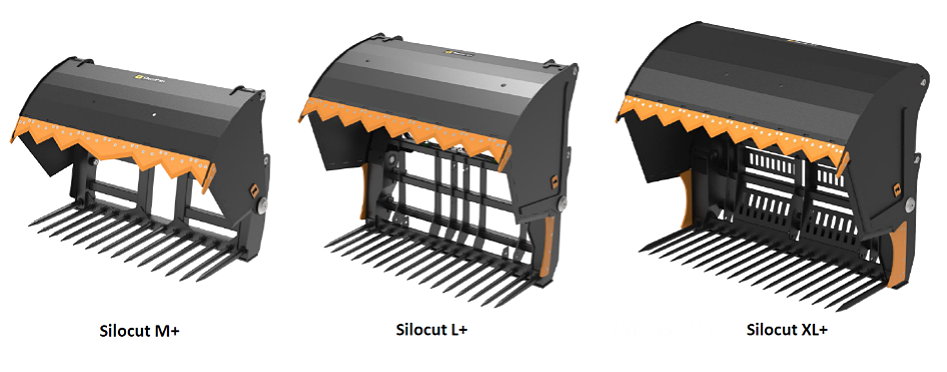

Available now, they come in three different sizes:

- Silocut M+: Available featuring high-quality, replaceable bolt on tines or a profile tine implement, a forged tine version which has profile cut “tufftines” welded in the tine carriage providing excellent wear capabilities. The Silocut guarantees a smooth and clean cut from silage stock pit to ensure high quality silage. The width and capacity are ideal for front-end loaders, compact wheel loaders and mid-sized telehandler use. Various accessories, such as bolt on back screens, allow end users to customise the implement to suit their personal needs.

- Silocut L+: Available with forged or profiled cut “tufftines”, but also a highly versatile bucket. The L+ is a highly efficient implement for both cutting clamp silage and splitting bales – no need for a second implement. It allows handling of different silage types, silage bales with the bucket also handling loose fodder and feed, again without changing implement when feeding animals saving valuable time. Powerful cylinders and a large opening allow most common silage bales to be split with ease, ensuring a complete cut with our unique cutting system incorporated into the side gables of the Silocut L+.

- Silocut XL+: This model is a high-capacity shear grab that can be used for cutting clamp silage and splitting bales. It’s offered in the same three versions as the smaller L+. The robust and well-tested design grants long service life and peace of mind.

Both the Silocut L+ and XL+ are available with two additional innovations. A bale wrap handler and a push out mechanism. The bale wrap handler makes it possible, after the bale is split, to grab the wrap and net and retain it, negating the need to remove the wrap by hand, increasing operator safety. The bale can be unwrapped, split and placed into the two separate feeder units or directly into the feed wagon or mixer in one process, giving substantial time savings.

The profile cut “tufftine” versions can be equipped with a push-out mechanism that facilitates the unloading into diet feeders or other areas with limited space.

“We have designed the new Silocut to facilitate the feeding process of our operators’ work and to simply make them more efficient,” Quicke’s Henrik Jönsson said. “Our brand-new design not only allows the operator to efficiently and cleanly remove silage from the silage clamp with less power, but also split and cut wrapped silage bales. Allowing our customers to work smarter, not harder.”

Quicke has also released a new sequencer valve that allows users to combine work with two independent hydraulic functions on the implement with only a third service. This allows the oil to divert to the bale wrap handler when the cut is completed, therefore ensuring that the bale is completely split and that the claws kick at the right moment as well. The valve offers great savings as the option can be used without the need for a fourth hydraulic service.

“We pride ourselves on the strength, quality, and durability of our products, and the Silocut range is no different,” Mr Jönsson added. “It’s been thoroughly tested both in a lab-based test rig as well as in the field at working locations around Europe. Customers who have tested the new Silocut were so satisfied they were reluctant to return the prototypes on completion of the field tests.”