Telehandlers have been part of the DNA of the Pontchateau site in Loire-Atlantique, France, for more than half a century. Before the year 2000, the factory used to manufacture the Sambron range of products, but after a succession of changes in ownership, it’s now Bobcat telehandlers that come off the production line.

All Bobcat rigid telehandlers for the global market are manufactured there, including 29 models split between ranges for the construction and agricultural markets. The factory was originally built on an 82,000 square metre plot that was extended to 95,000 square metres in 2019 to meet higher demand.

“In 2016, as our logistics capacity reached saturation and demand grew, Bobcat defined a three-year expansion plan for the facility, representing four million euros of investment,” the site director for the Bobcat Pontchateau facility, Jerome Miermont, said.

These developments have made it possible to meet the effects of substantial growth in the brand’s activity, which increased by 75 per cent between 2017 and 2022. This was also accompanied by a reorganisation of the manufacturing process.

For telehandlers, the journey always starts in the design office. This has a team of 40 employees operating from Pontchateau, together with another team based in the Czech Republic at Doosan Bobcat’s European headquarters.

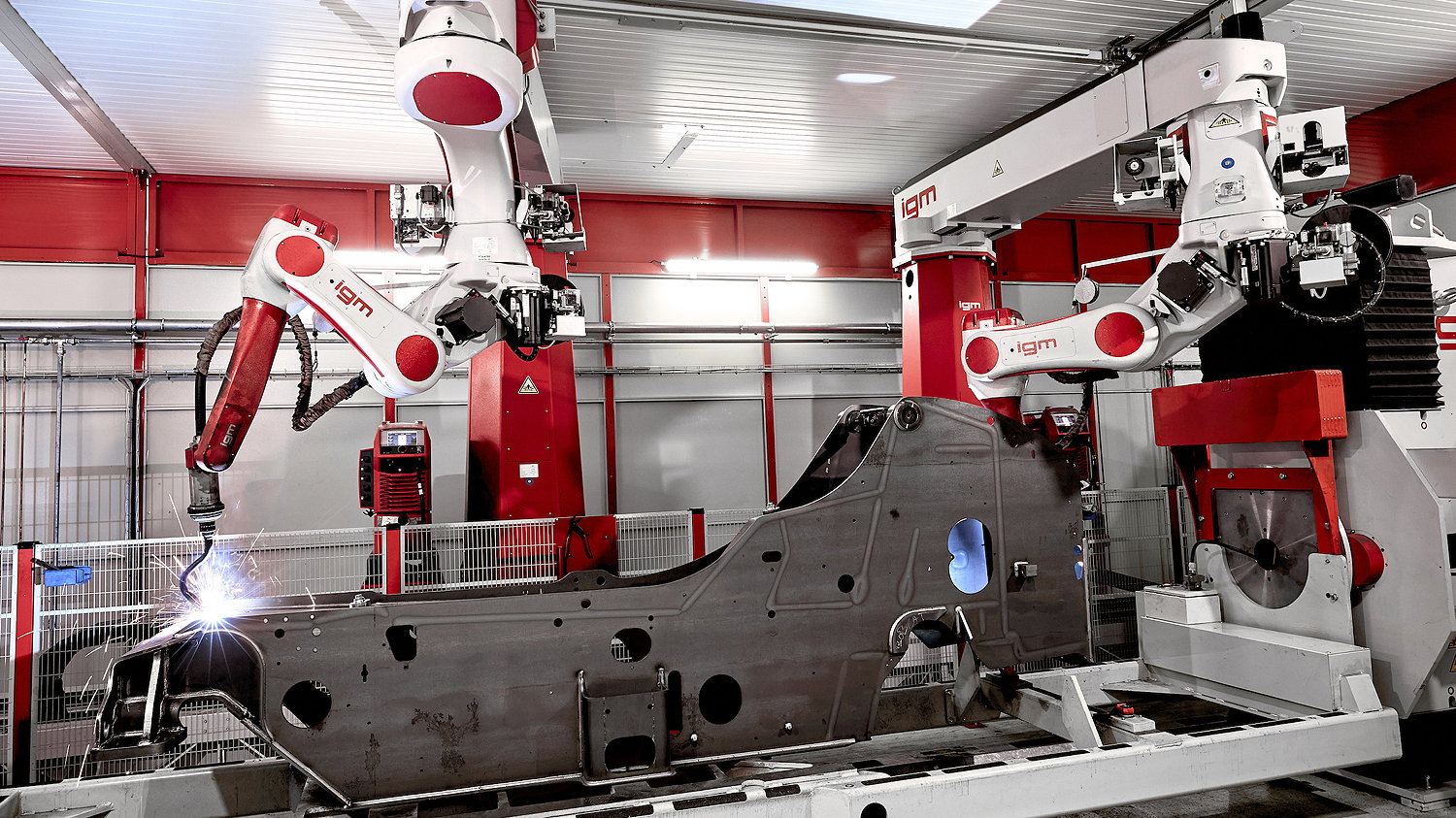

On the production line, the machines start to take shape during the mechanical welding operations that are strategically organised in two lines: one for the boom, and the other for the frame. After the steel parts have been laser cut, they’re bent into the right shape before welding.

“To optimise production, we’ve equipped ourselves with two larger robots, each of which welds all the frames, saving 30 per cent in time Mr Miermont said. “The second robot, representing an investment of 850,000 euros, arrived last September.”

The various parts of the telehandlers are then sent to the blast chamber for shot blasting, before being painted. The staff carry out a detailed technical procedure (priming, fading time, lacquer application and oven drying) to ensure a high-quality finish.

The assembly line is organised around 58 stations. To save time and space, a team in the kitting workshop has prepared the necessary components for each station in advance. On the sub-assembly line, various machine components (the engine nacelle, the cab and so on) are assembled to gradually build the machine on the main line, which alone comprises 17 different stations.

Even before the tyres are fitted, the carriage is filled with oil and programmed. This is followed by the fitting of the mudguards, a performance test and the installation of the tyres. The final assembly station is reserved for the installation of the hood and the stickers, then the machine goes through a test phase (static and dynamic) for four hours.

Up to 17 machines can be assembled daily.

“Last year we produced 2,658 machines,” Mr Miermont said. “This is a record number, much higher than the planned target of 2,455 units. But with an estimated annual production capacity of 3,500 machines in 2022, there’s still space for growth. The Pontchateau plant intends to double its activity by 2025.”