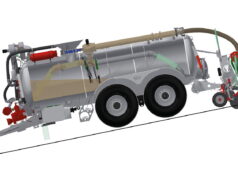

Pichon has launched its SV series, its first range of standardised tankers for organic liquid fertiliser spreading. The series comprises a number of pre-fittings designed to be scalable and capable of solving future challenges.

The machine’s pre-configuration, including through the manufacturers sales configurator, offers a cost-effective and reliable product, faster orders and improved and reduced delivery times.

With a view to eliminating the use of spreading equipment with the most emissions by 2025, the SV series design can adapt to various spreading methods thanks to its pre-configuration. These include: drip hose booms; trailing shoe booms; and tine incorporators. The range aims to offer the best delivery methods for organic products.

New with this series is an integrated chassis, compatible with undercarriage and tandem running gear, as well as an axle centre distance of more than 1.8m, allowing an optimised gross vehicle weight of 28t, 4.0t more than other makes on the market. These features make this tank one of the most competitive in its field.

This series also has a new iControl 7S steering system. Entirely developed by Pichon’s engineers, this tool, with an ergonomic and user-friendly seven-inch control touchscreen, manages spreading settings and provides reliable operation. In addition, combining a manual joystick and a monitor makes all tool-handling operations more straightforward.

The iControl 7S allows the user to completely optimise their work thanks to automated filling, transport and spreading cycles. With real-time feedback on the screen, the data collected will enable cycle monitoring and tracking.

Pichon has chosen a new, internally developed and controlled electronic architecture to manage and track maintenance.

In an effort to constantly improve, we take great care to develop our material. The new unloading pipe, available as a 200mm inner/upper pipe, notably features a standardised stone trap to collect foreign materials during the spreading cycle.

Additional options are available in the pump circuit to improve discharge flow and control doses according to organic matter, including a hydraulic turbo feeder and flow meter combined with a flow regulation system.

The new components on the hydraulic distribution box provide simultaneous running of several engines (turbo feeder and tool macerators), ensuring transverse distribution during spreading.

Pichon applies its manufacturing expertise to offer customers an efficient after-sales service through its network of distributors. Particular attention is being given to this new series to assist its network, with a new dedicated MyParts website to view all technical documentation for the product including user manuals, spare parts and so on.