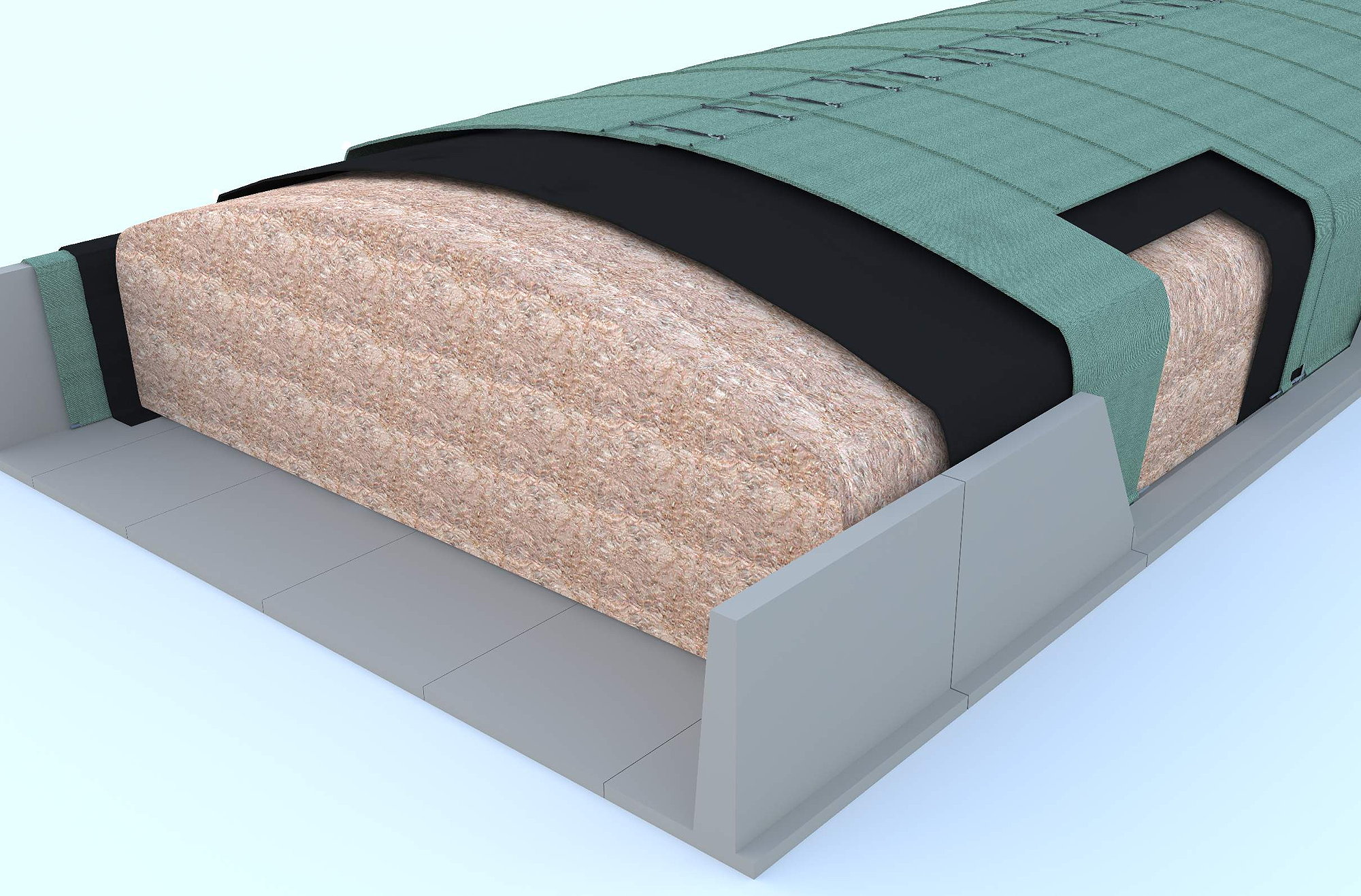

A unique concept in covering silage is now available from forage preservation specialist Kelvin Cave Ltd. The Silage Safe system requires no weighting on top of the clamp, dispensing with the need for tyres, gravel bags or any other ballast.

Instead, the clamp is sealed by a series of straps that are tightly ratcheted into place. This makes one of the most unpopular jobs at the end of silage making a potentially two-person operation. The straps can also be tightened during the course of the crop’s storage, which ensures a full and even tension is achieved across the clamp. This helps avoid the creation of air spaces as the silage settles.

A further benefit of the system is its application and removal in two-metre sections. This is just as useful at the time of feed-out as it is at covering, speeding up the process and avoiding the need to move weights. Each section can then be stored on racks for use the following year.

This is the first year Silage Safe has been available in the Britain for the grass silage season. However, several forage producers were early users of the system for maize silage last autumn. These include a dairy farmer in an exposed coastal location and an arable farmer in East Anglia covering maize for anaerobic digestion.

A&EG Heading Ltd covered a clamp on its Cambridgeshire farms measuring a massive 100m x 30m, with a height 6m. This is believed to be the largest ever clamp covered with the system anywhere in the world.

Farming about 2,750ha and cutting 360ha of maize last year, farmer Marc Heading, said he was absolutely determined not to have a clamp covered in disused tyres and wanted it to be relatively easy to manage. The estimated 14,000t of freshweight in the clamp is used as feedstock, together with wheat straw, for the company’s 5mW gas-to-grid anaerobic digester.

“The covering system is projected to achieve payback in one to two years through a reduction in dry matter losses that could otherwise easily occur through aerobic spoilage,” Mr Heading said.

Silage Safe is equally suitable for smaller farming operations, being bespoke for every clamp. On the South Wales coast, dairy farmer Hopkin Evans also used the system to cover maize last year for his 180-head herd. A key feature for Mr Evans was the product’s wind-resistance, assisted by being firmly anchored in place inside the clamp.

When the maize harvest was completed in October, it was just his family left on site for the job of sheeting and covering the clamp. Once sheeting was complete – using O2 Barrier 2in1, the single sheet that transforms into two – the Silage Safe netting just needed closing and tightening.

“Sheeting and covering the clamp has always been such a physical operation, but this was really easy,” Mr Evans said. “I’ve never done it with just my wife and parents before, and the whole process took less than two hours.”

For the future he plans to add more of the new covering systems to the other clamps on the farm.

“I did deliberate hard before buying the Silage Safe system, but I’ve no doubt we did the right thing,” he added. “I can see this product easily lasting 10 years, but I’m confident it will return its investment in two to three years. The greatest damage caused on our farm is when anything flaps in the wind, but this covering just stays in shape and in place – it doesn’t move at all.”

Distribution of Silage Safe in Great Britain is exclusively through feed and forage preservation specialist Kelvin Cave