Amazone’s Pantera concept has meant larger farms and contractors have the ideal tool to cope with all the challenges in crop protection application being thrown at them. This self-propelled sprayer range combines ultra-modern technology with high-tech management systems, and for 2017 the Pantera, Pantera-H and Pantera-W will receive some exciting new features.

The heart of Pantera 4502 is the proven six-cylinder Deutz engine with a power rating of 218hp. The in-line engine, with turbocharger and intercooling for highest performance requirements, provides – thanks to the intelligent engine management in Eco mode – minimal fuel consumption. If, however, more power is required, for instance when working on steep slopes, then the Power mode is always available to the driver that enables them to obtain maximum power at 2,200rpm.

The latest Pantera meets the Stage IV emission standard, using a combination of exhaust gas recirculation, slective catalytic reduction with AdBlue, a diesel oxidation catalyst and a diesel particulate filter (DPF). The new 20-litre AdBlue tank is positioned at the side of the machine’s 230-litre diesel tank, and AdBlue consumption is approximately 2.5 per cent of the fuel consumption, meaning that the tank only needs refilling every three or four diesel tank fills.

Apart from the changes to the exhaust system, additional alterations and improvements are also introduced with this model change. The external distinguishing features include a new tank access ladder on the right machine side and new LED rear lights. The new Pantera models can also be equipped with LED work lights instead of the standard Halogen lights if desired.

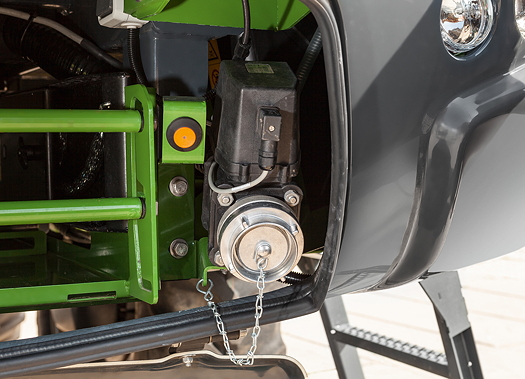

Furthermore, the suction capacity of the Pantera is increased by 20 per cent up to a maximum of 600 lit/min with the aid of an injection system. In this way, the Pantera is filled in less than 10 minutes, and to aid headland filling the bowser fill port has been relocated forwards into the storage compartment under the cab, and comes as standard now with automatic fill stop. This automatically prevents any potential overfilling of the machine.

Inside the operator station there have been many changes to the layout of both switches and hoses to improve operator comfort, plus the pumps have been rehoused to reduce noise levels for the operator when filling. New tyre sizes and mudguards finish off the options list.

Moreover, the Pantera can also be ordered in the Pantera+ version. Thanks to the alternative drive wheel reduction gearboxes, it offers more than 25 per cent better climbing ability. This option has been especially designed for extreme conditions in hilly terrain. Whereas the standard Pantera with a full tank can negotiate a slope of approximately 27 per cent, the Pantera+ can travel on a slope of approximately 34 per cent.

The Pantera-H is the specialist model for spraying in tall crops. It features hydraulic height adjustment that, at the press of a button, can increase the ground clearance of the machine from 1.25m to 1.70m. However, all Pantera models have three further special options to aid crop flow: well-rounded outer covers let the crop gently slide past the sprayer’s gearboxes, while a crop divider, which is attached in front of the four tyres, is offered to gently guide the plants at the headland, or when entering the row, past the wheels. In addition the Pantera can also be equipped with an underbody protection plate to avoid damage to plants that are being pushed underneath the machine.

AmaSelect continues to be the nozzle control system of choice for the Pantera, with up to 85 per cent less overlap than a conventional sprayer boom fitted with spray line sections, as well as enjoying the benefit of automatic nozzle size selection by speed and spray rate to ensure maximum chemical efficacy.

For more information visit: www.amazone.co.uk.