Nowadays, the composition of feed should be matched exactly with the individual needs of the stock being fed, whether they’re suckling piglets, finishing animals or sows. Only if the ration mixture is correct, is optimal performance possible.

Nowadays, the composition of feed should be matched exactly with the individual needs of the stock being fed, whether they’re suckling piglets, finishing animals or sows. Only if the ration mixture is correct, is optimal performance possible.

Independent of the kind of feeding system employed, it’s also important that the individual feed components are mixed efficiently.

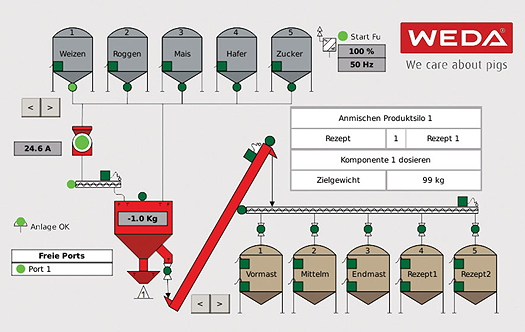

With the help of the new mill control system from WEDA Dammann & Westerkamp, the workload of in-house feed production and feed administration can be reduced. The new system also ensures exact measurement and mixing of the feed ingredients.

The easy-to-handle control module – that’s compatible with all customary feeding systems – visualises the components as well as the mixing procedure of the unit via a touch screen.

With the help of a convenient display, the mixing unit can be completely controlled and operated by this remote control. Via the intuitive user interface, the process can be operated with up to 15 feed components, 10 product silos, a grain mill, a discharge screw conveyer as well as a dry mixer.

Here, users can choose between the automatic and the manual feeding mode, and up to 10 stored recipes can be accessed. A minute-by-minute adjustable control of the day’s schedule, with a mixing and allocation program, makes the preparation of the pigs’ feed even easier.

Data used by the system can be backed up via a USB or ethernet port.

As well as monitoring the conveying processes, sensors in the system report the filling levels of the ingredient silos so that there’splenty of warning before they’re empty.

For more information visit: https://weda.de/en/.