The Profitable Farming Company (PFC) will be exhibiting the latest Harvest Tec 600 Series Isobus-ready advanced moisture monitoring and automatic preservative application system at this year’s Grassland UK. The new system is specifically designed for use with all makes and models of balers for both hay and straw.

The potential to increase baler output and forage quality benefits that the Harvest Tec application and preservative system offers, has been recognised by a number of leading baler manufacturers that have adopted their own branding to show the importance they place in these products. Agco (HayBoss), Kuhn (Balers Choice), Case IH (Thirty Plus) and New Holland (Crop Saver) all offer the system as an option for their baler ranges and will have demonstration units fitted to balers on their stands and working plots.

The Harvest Tec 600 Series variable-rate applicator is the most advanced moisture recognition and modular system on the market, and allows the customer to tailor the Harvest Tec equipment that’s best suited to their operation. It provides operators with greater flexibility and ease of use.

The 600 Series is integrated with Agco 21/2200 series balers, Case IH LB and New Holland Big Baler and Isobus-compatible tractors, ensuring that essential application data is displayed alongside the baler information on the Isobus display in the tractor.

For non-integrated balers or tractors with dual or spare Isobus connectors, there is an optional interface that enables information to be displayed on a split screen or on a separate screen, including the Harvest Tec Touch Screen display. This can also be used to control applicators on tractors and balers without Isobus.

The ability to accurately and automatically apply buffered Baler’s Choice preservative to hay and straw crops in less than ideal conditions, or in order to maximise crop yield and feed value, enables baler operators achieve high bale quality at moisture contents of up to 30 per cent, without dust and mould developing. In good conditions, being able to bale at more than the safe 15 per cent moisture content, baling can start earlier in the day and finish later into the evening, resulting in up to 30 per cent higher daily outputs and increased profitability.

The Harvest Tec 600 Series system is designed specifically for use with all balers from small square, round and the highest capacity big square balers. In addition to providing accurate moisture content readings and automatic variable rate application of Baler’s Choice buffered preservative, the 600 Series can offer the operator the option to provide full bale traceability from the field to end-user, yield mapping and visual identification of high moisture content bales.

Two versions of the Harvest Tec 600 Series system are available: Moisture Monitor and Moisture Pro. The 600 Series Moisture Monitor option is designed for operator’s who just want an accurate moisture monitor and are unlikely to want to add any other function modules. Using star wheels located in the bale chamber that take nine readings every second, this provides an accurate record of the moisture content over a range from eight per cent to 72 per cent, accurate to one percentage point. This information is displayed on a compatible baler or tractor terminal or the Harvest Tec display.

If it’s then decided that additional modules are required, these can be added, but only after a companion kit has been installed to upgrade the system to Moisture Pro. This provides the same moisture monitoring functionality, but with additional features and functionality.

Modules that can be added include:

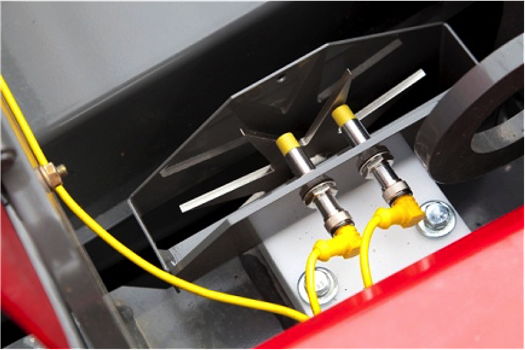

- The Baler’s Choice Automatic Variable rate Applicator module uses the moisture content and bale length data recorded by the star wheels to automatically adjust the application rate relative to the moisture content of the bale. On baler’s fitted with a weigh scale, this data is also recorded and used to further increase accuracy.

- The Bale Marker module provides an easy and cost effective way of highlighting bales with wet spots that are above a required level and sprays a food grade colour to indicate areas of the bale where the moisture content is above the operators defined level.

- The Bale Tagging module records bale location and application data onto a RFID tag, which is attached to the bale string, to provide full traceability from field to end user, inventory control and quality control.

For round and small square conventional balers, two systems are available: the 600 Series and 400 Series. Like the systems for big square balers, the 600 Series for round and small square balers is Isobus compatible and uses highly accurate moisture sensors within the chamber to monitor crop moisture and use this information to automatically alter the application.

The 400 Series uses similar technology, but is not Isobus compatible and is designed as an entry-level system for lower output round and small square balers. For the operator only producing a wrapped product the company also supplies a simple electric pumping system for fixed-rate silage inoculant application.

For more information visit: www.profitablefarming.co.uk.