Fliegl has improved its Skate trailing shoe distributor so that it adapts even better to uneven ground. The new Skate 150 model, meanwhile, allows a smaller distance between the trailing shoes to be selected.

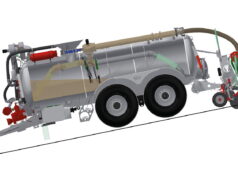

Applying nutrients in a targeted and dosed manner is the benchmark for modern fertiliser technology, and Fliegl claims to provide significant support here with well thought-out spreading technology close to the ground. The universally popular Fliegl Skate trailing shoe distributor applies liquid manure efficiently and powerfully. With the help of its spring-loaded slotted shoes, it lays down the manure in bands 250mm wide.

Now, Fliegl Agrartechnik has introduced another version, the Skate SD, that has a shoe spacing of just 187.5mm. This has the advantage that more manure bands at a closer distance are placed on the ground. At the same time, the amount of liquid manure applied per hose is reduced.

The trailing shoe distributor gains added value through the perfect application of the liquid manure because there’s a better infiltration of the substrate, especially since the individual manure band contains less substrate. Highest precision with a fabulous lateral and longitudinal distribution round off the picture.

Spreading in tall crops is said not to be a problem, despite the narrower band spacing.

The Skate SD will initially be offered with a 12m and 15m working widths.

Fliegl has also introduced a feature meaning that the cylinders of the distributor arms switch to the floating position during the application process. This guarantees optimal ground adaptation, especially in uneven and hilly terrain. In addition, this results in a better distribution of forces on the linkage, which above all results in less wear.

As soon as the headland button is pressed, the load on the folding cylinders of the side arms is released and the distributor swings up into the headland position.