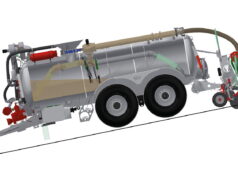

Danish manufacturer Samson Agro has introduced its new Samson PGII Genesis slurry tanker series to supplements the existing PGII series that the company has been producing since 2013. The new machines have been designed to be fitted with the largest possible low pressure tyres, and has improved implement carrying capabilities.

The Samson PGII Genesis is available in two versions: the two-axle PG1118 Genesis and PGII20 Genesis with capacities of 18 and 20 cubic metres respectively; and the three-axle PGII28 Genesis, PGII31 Genesis and PGII35 Genesis with approximate capacities of 28, 31 and 35 cubic metres respectively. The final capacities depend on the options selected for each tanker.

The PGII Genesis series features technologies and properties that are setting a new standard for efficient and accurate slurry application. The two-axle Samson models are designed to accept tyres up to 1,950mm in diameter and 800mm wide, while the three-axle models can take tyres up to 1,850mm in diameter and 800mm wide. These allow for optimal distribution of pressure on the soil during slurry application.

Tyre pressures can be easily regulated up or down when driving from one surface type to another, for example from road to field, or depending on the soil and crop type in the field, using automatic tyre pressure regulation.

This tanker series is also available with the newly developed Samson Hydraulic Power Drive (HPD) or the already well-known Hydraulic Wheel Drive (HWD) wheel drive. They both offer hydraulic power transmission from tractor to tanker that provides traction on one of the slurry tanker’s axles. The wheel drive ensures maximum traction even in difficult terrain such as hilly or wet ground conditions and contributes to reduced pressure, wheel slip and driving damage in the field.

In addition to the dynamic driving experience, Samson has also focused on the tanker’s implement-carrying properties during development of the PGII Genesis. In particular, axle positions and weight distribution have been important parameters in terms of allowing maximum freedom to choose the injector or boom for the slurry tanker that best suits a given application task, while maintaining good driver comfort.

“The development of the PGII Genesis has been carried out in close cooperation between the development department at Samson and a number of farmers and agricultural contractors,” the company’s product manager for slurry technology, Niels Haubjerg, said. “We’re therefore sure that we have a new type of tanker here capable of solving a requested task in the field and thus setting new standards for slurry application.”

Application with the Samson PGII Genesis is, like the PGII, intelligently controlled with Samson’s SlurryMaster 8000 control unit that, in combination with the tough unloading pump and built-in flow control system, ensures efficient and accurate dosing, and placement of the slurry to benefit the crop, the farmer’s yield and the shared environment.