Norfolk-based Prior Power Systems has started marketing the Australian designed-and-built HYDI diesel engine hydrogen injection system in the UK to help operators reduce both diesel costs and the environmental impact of their machines.

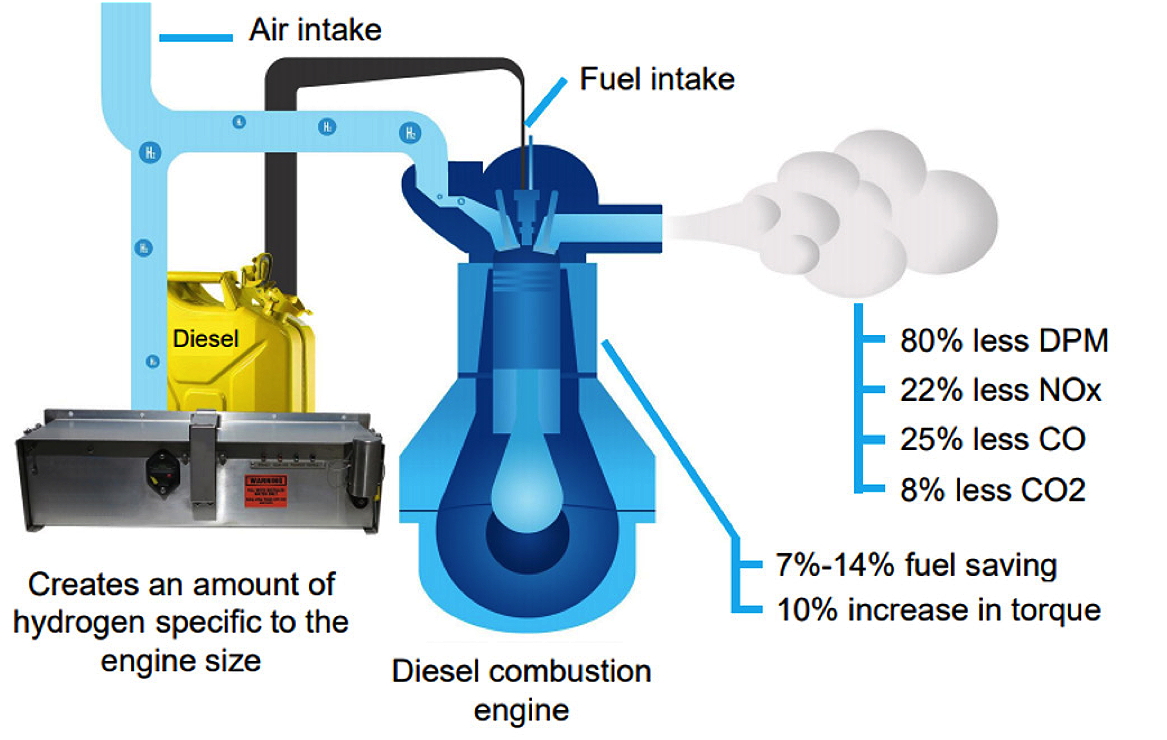

The system is said to be able to decrease diesel consumption by up to 14 per cent, while simultaneously increasing the power output, with up to 10 per cent extra torque, and reducing harmful emissions. The cleaner burning engine also means longer service intervals with the associated savings.

HYDI is suitable for both static and mobile machinery, and as no hydrogen gas is stored, it is promoted as a safe way to harness hydrogen power. The self-contained system uses electrolysis to split ionised water into hydrogen and oxygen. The hydrogen gas is them pumped into the air intake of the diesel engine to be used as fuel.

Because hydrogen has three times the energy density of diesel, the quantity of gas that needs to be injected into the air intake is small; the engine is then capable of a cleaner and more complete burn, and less diesel is needed.

The technology includes sophisticated electronics that adjust the hydrogen flow to optimise engine performance for any given load. While the system works best when it can communicate with the host engine’s ECU, it will also work with much older older engines without an ECU, although a bit of fine-tuning is needed to find the best operating “sweet spot”.

Fitting is straightforward, with no engine modifications required. The pipe that delivers the hydrogen is simply introduced into the air intake sysyem. The HYDI system can work with 12- or 24-volt electrical systems, and draws between seven and 30 amps depending on the application.

Hydrogen output from the system is about 0.7 lit/min, although this varies depending on the engine setting. This consumes about 27ml of demineralised water each hour, meaning a litre will be sufficient for 37 hours of constant running. The HYDI units have a built-in 2.3-litre water tank.

The business development manager at Prior Power Solutions, Paul Dekker Kleyn, said the Hydrogen-Diesel Introduction system was retrofittable to existing and new diesel engines.

“It effectively converts a standard combustion engine into a dual-fuel engine,” he added. “It’s a stand-alone system that produces hydrogen gas from water by electrolysis, which is injected directly into the engine reducing fuel consumption as well as harmful emissions.

“While sceptics might be nervous about hydrogen technology, this system is completely safe because, crucially, no hydrogen is stored.”