The world’s first electric infinitely variable transmission with electro-mechanical power split is now an option for John Deere’s top-of-the-range 8R410 and is available for all three machine forms – 8R wheeled, 8RT and 8RX.

This is a significant step in John Deere’s journey towards electrification that has been developed in partnership with Joskin. The entirely new transmission concept, inclusive of an e-port for implements, was awarded a gold medal at Agritechnica 2019 by the DLG (German Agricultural Society).

After many years of research and development in the space of electrification, John Deere has now found a highly durable solution offering an infinitely variable transmission in the horsepower class above 400hp. Not only does it have increased durability, but it also positively impacts the overall performance.

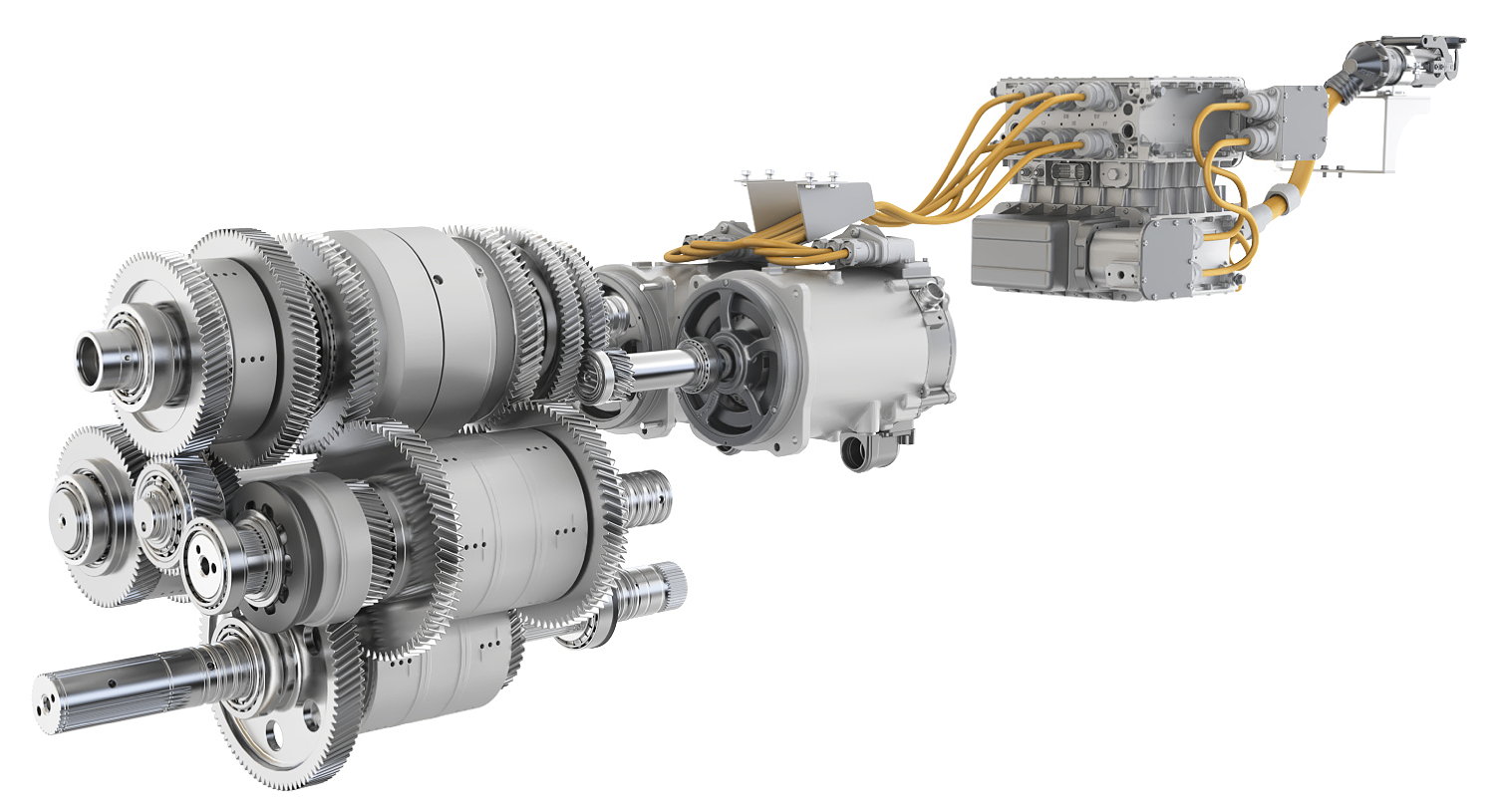

For the new eAutoPowr, John Deere has completely replaced the hydraulic components with an electric power path. The two brushless electric motors are virtually wear-free and powertrain durability exceeds any other concepts previously offered in the industry. Moreover, this simplifies the design of the transmission and allows real time remote technical diagnosis.

The electric drive is designed in such a way that it not only supplies the drive, but also provides up to 100kW of electrical power for external implements via 480-Volt variable-frequency three-phase alternating current (AC). A first application has been developed by John Deere together with Joskin. In combination with the Joskin axle drive, two axles of the slurry tanker are driven electrically and thus the weight of the tanker is utilised for traction. This means increased traction, less slippage and precise tracking.

The tractor can perform at optimum with less ballast or further increase productivity by having the ability to operate wider implements with the same tractor. With the help of the e-Drive, the electric drive is activated to prevent any wheelslip from occurring. The slip limit can be set by the driver. This allows the system to support the tractor permanently or only in certain situations, for example, when going uphill.

In addition to the technical innovations, driving comfort is not neglected. In the already very quiet driver’s cabin, the noise level is reduced even further. The driver also benefits from the fine speed control and improved acceleration. Since speeds of up to 5km/hr are driven completely electrically, a fast and very smooth transition is possible.