Slurry equipment manufacturer and contractor Tramspread is still seeing increasing demand after 25 years for its contractor engine-driven pump unit (EDPU). The Suffolk-based company is also celebrating 15 years production of its popular random wrap hose reel.

Managing director Terry Baker said the company started umbilical contracting 25 years ago with a single-axle EDPU that enabled one tractor to carry everything needed.

“Following the introduction of the random wrap hose reel, our contracting trailers were modified to carry 1,000m of detachable hose reel spool and were equipped with a front three-point linkage allowing us to carry the random wrap reel coupled with a further 1000m of hose on the front of the tractor,” he said.

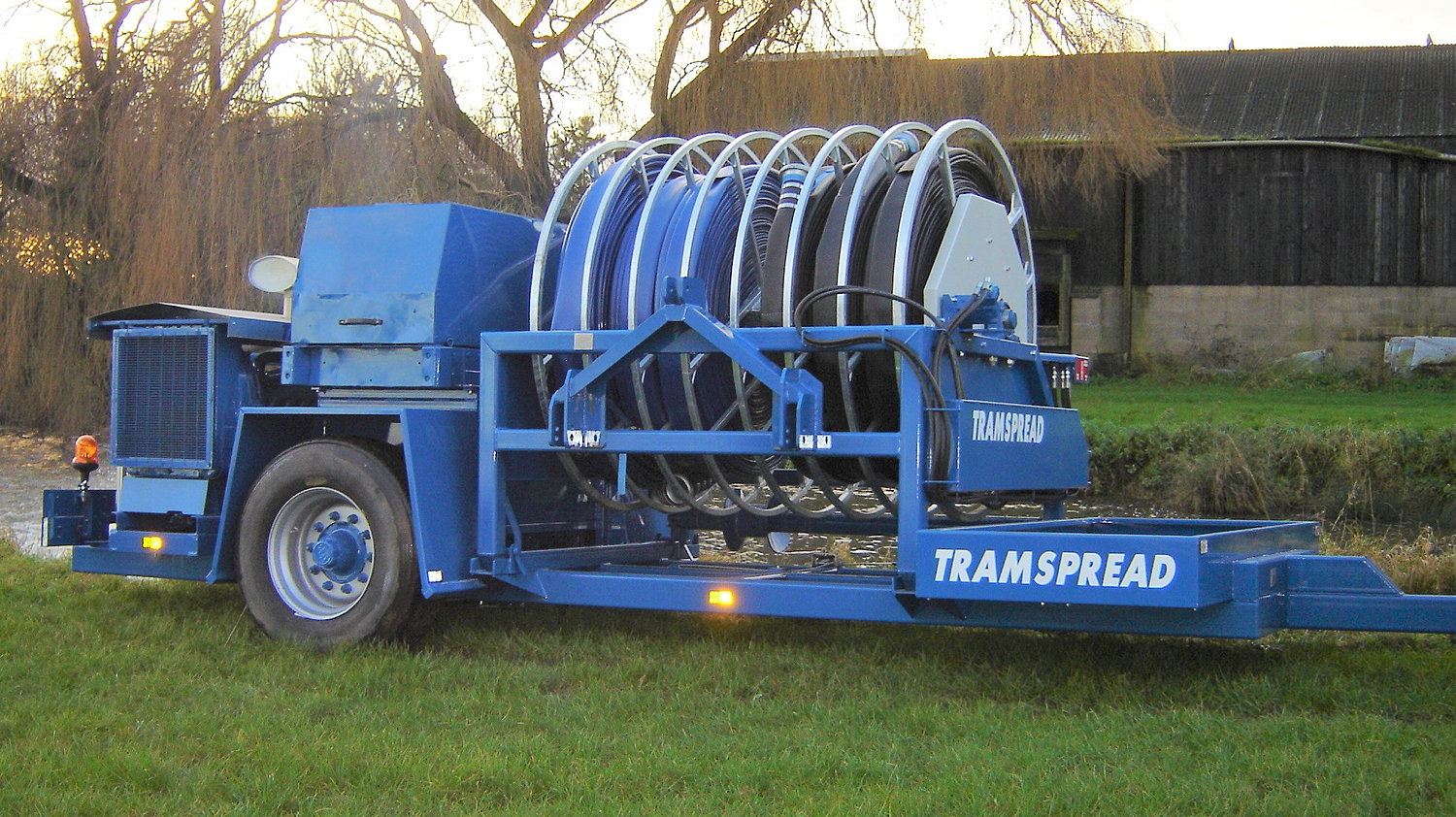

The contractor trailer evolved to a twin-axle model that was introduced in 2012. It has an extended chassis enabling it to carry two 1,000m detachable hose reel spools and, if needed, a further 1,000m on the front three-point linkage to provide a total of 3,000m.

Using the contractor trailer, Tramspread Contracting applies more than 450,000 cubic metres of slurry and digestate annually, with up to 70 per cent being applied in the spring as a top dressing.

“All slurry applications are monitored and recorded using John Deere’s Green Star, a Krone flow meter and Ravenbox software linked to the tractor’s ISObus network,” Mr Baker said. “This allows us to record the applied rate per hectare and total cubic metres applied.

“With the use of an Agros N testing kit, we can also advise our customers of the applied available nitrogen per hectare too.”

In 2007, Tramspread manufactured the first Random Wrap Hose Reel after Mr Baker had seen similar units being used in Holland. The reel is made with a twin hydraulic motor drive and drop out spools.

“This allows one three-point linkage frame to handle many spools, making it very cost effective,” he said. “The spool has a capacity of 1,000m of both four- and five-inch drag hose.”

At the same time, Tramspread introduced Storz hose end couplings that revolutionised the laying out and picking up of the drag hose.

“The combination of Storz couplings and the power of the twin hydraulic motors enabled 600 to 800m of drag hose to be reeled in one length,” Mr Baker said. “This removed the need to couple and uncouple every 200m length of hose, necessary with a segmented conventional hose reeler.”