German manufacturer Bergmann, known for its innovative spreader technology and superior distribution accuracy, has revealed a number of developments focused on its V-Spread wide spreader unit, optimisation of distribution accuracy and connectivity to the independent agrirouter data exchange platform.

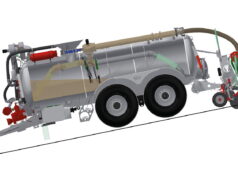

At Agritechnica 2019, Bergmann presented the unique, patented V-Spread wide spreader unit with a material-dependent working width of up to 36m and an ideal spread pattern for its twin-axle TSW5210 and TSW6240 series universal spreaders and the three-axle TSW7340S universal spreader. From the 2022 season, V-Spread will now also be available for the TSW2140E low-bed universal spreader.

The effective combination of the V-shaped spreader disk arrangement transversely to the driving direction and an increased spreader disk diameter makes for a more even material distribution over the disks and therefore a perfect distribution on the field.

Advantages of V-Spread over standard spreaders include:

- greater working widths at top spreading quality;

- fewer passes per area and therefore less soil compaction;

- use of tram lines also possible at more than 24m;

- increased throughput; and

- reduced spreader wear through fewer passes.

V-Spread requires a tilling roller cardan drive. This ensures convenient and low-maintenance operation and is much quieter than a chain drive, making the driver’s work easier. Bergmann is the only manufacturer to offer the cardan tilling roller drive, complete with all its benefits, from the smallest to the largest universal spreader (8 to 34t permissible gross weight).

Bergmann’s new, optional ExaRate weighing compensation system will allow an even more exact fertiliser distribution than the company’s current proven weighing system.

Integrated in the ISObus software, ExaRate continually monitors the weight reduction during spreading, compares it to the specified distribution quantity (t/ha) and continually adjusts the actual distribution quantity to the specified distribution quantity.

The result is exact distribution under many conditions – a feature demanded by users especially for expensive and sensitive materials, such as lime, dry poultry manure and sewage sludge. This makes the organic fertiliser go even further, supplying the soil with just the right amount of nutrients for a higher crop yield.

The ExaRate control concept also allows variable rate control (VRC) for section-specific cultivation using application maps.

Bergmann has also started the new season with a small pilot series of its revised lower tailgate for the TSW5210S/W series of universal spreaders and higher series models.

Although in the standard version, the adjustment will still be done manually, there will now be a single, central adjustment spindle rather than the two threaded spindles at the sides. A convenient hydraulic adjustment option from the driver’s seat will also be available.

In addition, the shape of the spread pattern limiter has been optimised to allow even more exact spreading at headlands. The shape of the spread pattern limiter is based on the design of the V-Spread wide spreader unit.

Since 2020, Bergmann has been a partner in the agrirouter consortium. Agrirouter is a neutral, generic web-based platform for data exchange between machines and agricultural software of different makes.

All Bergmann vehicles are ISObus-compatible. If they feature the optional ISObus function as well as a CCI 800, CCI 1200 or other ISObus- and agrirouter-compatible terminal, they can conveniently transmit machine, GPS and job data in ISO XML format to the desired end points via terminal and agrirouter.

With agrirouter, the user can specify what data will be transmitted to various agricultural software systems, such as a farm management information system (FIMS).