Claas’ “Future Factory” tractor assembly plant at Le Mans, France, has officially started operations following three years of modernisation. Drawing on state-of-the-art digital technologies, the facilities sets new standards for tractor production.

Claas gave the go-ahead for the major investment at Le Mans back in 2017. Investments totalling 40 million euros were primarily spent on a complete renewal of assembly equipment and digital transformation of the plant. This brings the total investment at Le Mans, the development centre in Vélizy and the test-and-validation centre at Trangé to about 80 million euros since the acquisition of Renault Agriculture in 2003.

“Our completely refurbished plant at Le Mans raises the bar for the production of premium and connected agricultural tractors,” the chairman of the Claas Group executive board, Thomas Böck, said. “We’ve therefore opened a new chapter in the continued growth of our global business.”

Back in 2019, the modernisation efforts were identified as a lighthouse project in France and labelled a showcase for the industry of the future.

Modernisation of the plant creates entirely new opportunities for the manufacture of increasingly complex and individually configured tractors. This involved a complete rethink of many complex processes – especially in the area of in-house logistics. The use of cutting-edge virtual reality technologies enabled digital simulation of all processes during the factory planning stage, even for tractor models that haven’t yet entered production.

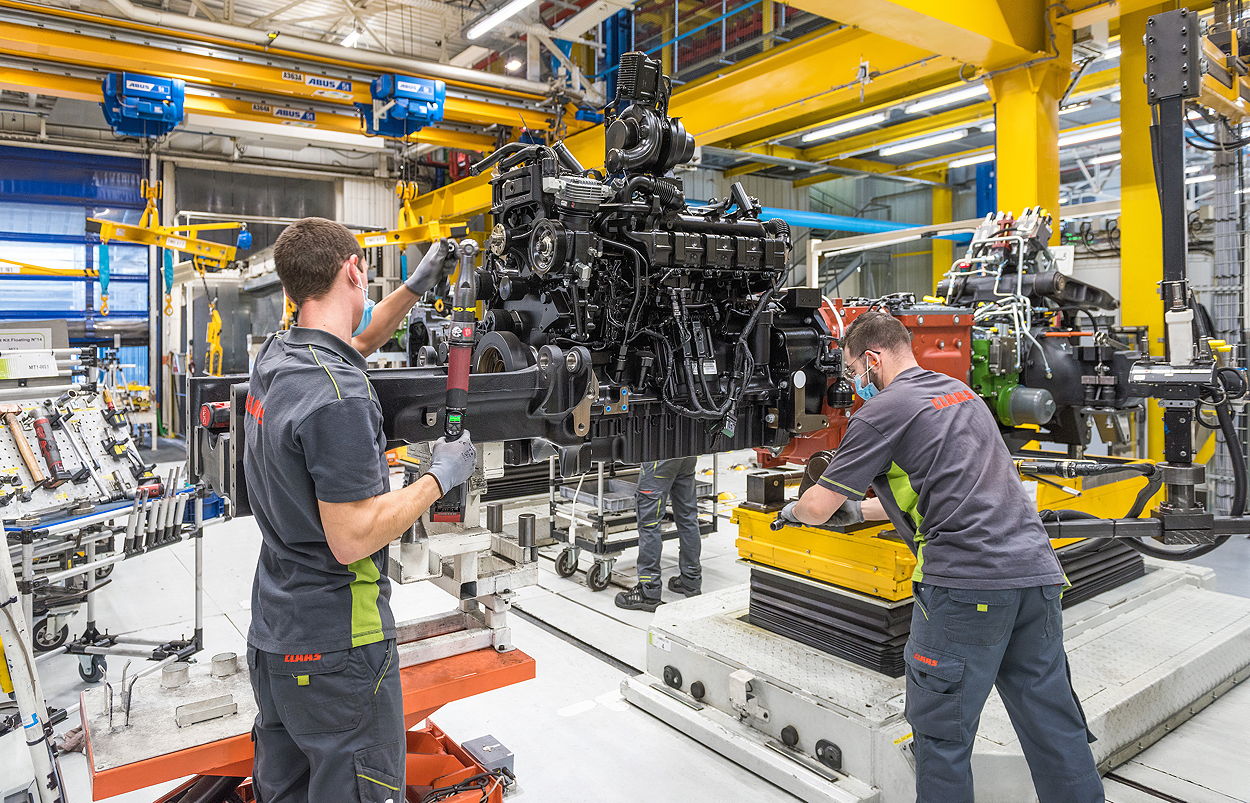

Innumerable options were acted out using 3D animations and VR goggles in order to play through all stages of assembly, from the powertrain to the finished and tested tractor. Any necessary structural changes were therefore identified early on. The introduction of automated guided vehicles (AGVs) made a significant contribution to the automation of production. 40 of these driverless and fully automatic carrier vehicles transport the tractors from the first to the last assembly station, and are capable of moving up to 20t at a time – meaning they provide sufficient load capacity for all current series, as well as for future higher-performance models.

In future, daily production will therefore be increased to as many as 60 tractors a day. Projected to the full year, this can lead to an annual production capacity of more than 13,000 tractors compared to about 10,000 units today.

Employees are the main beneficiaries of the completely modernised plant. The new logistics infrastructure means employees have significantly more space at their ergonomically designed workplaces, as only parts that are immediately needed are delivered to the assembly line. Some of the workstations are even equipped with headsets so that employees can benefit from easier communication. In addition, state-of-the-art LED lighting technology ensure a concentrated and pleasant working atmosphere that resembles natural lighting conditions.

“Besides efficiency, the work conditions were our main priority in designing the new manufacturing facility,” the head of Claas’ tractor unit and group executive board member Dr Martin von Hoyningen-Huene said. “We’ve achieved a substantial improvement in workflows and ergonomics that’ll help to increase the concentration and motivation of our staff. Like the new logistics, this is a fundamental ingredient for the production of tractors according to the most rigorous quality standards.”

At present, five tractor model series from 75 to 460hp are produced at Le Mans. Together with the development centre at Vélizy, near Paris, and the test and validation centre at Trangé, about 1,000 people are employed at Le Mans. The locations co-operate closely with Claas’ other development centres and plants.