Engineers at Pöttinger have delivered a key innovation with the company’s new optional glide bar that replaces the jockey wheel on the Top 842C rotary rake Dirt ingress is reduced by tracking the entire surface of the ground close to the tines, and the innovative guide bar comes into a class of its own on wet and peaty soils with deep wheel marks.

Engineers at Pöttinger have delivered a key innovation with the company’s new optional glide bar that replaces the jockey wheel on the Top 842C rotary rake Dirt ingress is reduced by tracking the entire surface of the ground close to the tines, and the innovative guide bar comes into a class of its own on wet and peaty soils with deep wheel marks.

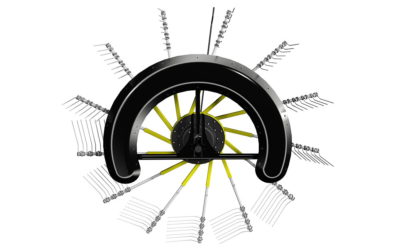

The wheels used on the chassis of rakes are configured in various ways (tandem, pendulum axles, different number of wheels) with jockey wheels fitted at different locations , and these try and ensure the best possible tracking of the ground to reduce pulling dirt into the forage.

The innovative feature of the new Flowtast glide bar is the wear-resistant plastic that’s used as the ground contact material. Its high-volume sabre shape delivers the best gliding characteristics even when moving sideways.

The glide bar is very cost effective and therefore has a positive effect on yield: the suspension properties of the glide bar allow an approximately 10 per cent higher driving speed. Thanks to lower vibration and smoother running as a result, the rake is subject to a much lower level of wear. Downtime is reduced because repairs to worn or bent jockey wheel units are no longer necessary.

A higher milk yield also increases profits. This is achieved by reducing dirt ingress to the forage. Even in very difficult ground conditions, the glide bar provides uniform full area tracking to hold the tines at an ideal distance to the ground.

The Pöttinger Flowtast glide bar excels in problematic conditions, such as wet or peaty soils, when working with wholecrop with an open sward, where there are deep tyre marks in the field (tramlines, irrigation system marks) or in areas damaged by wild boar or grazing animals.

For more information visit: www.poettinger.at.