Germany’s Maschinenfabrik Kemper has announced a strategic agreement with Scherer Inc of the United States to better serve existing and future Kemper customers by offering kernel processors and rolls for various self-propelled forage hervester (SPFH) brands.

John Deere has been installing Scherer processors in their forage harvesters for the past year, and Kemper is taking over the distribution rights for Scherer kernel processors and replacement rolls for other forage harvester brands in Europe, the Far and the Middle East, as well as the CIS states, Asia and South America, effective immediately.

“This agreement allows us to expand the Kemper forage harvester product portfolio to better serve our customers,” said sales and marketing manager Georg Wigger. “After an in-depth evaluation of the global forage harvester business, we determined that Scherer products would most effectively enable us to serve our customers and expand our overall product line-up.

“The entire kernel processor product line will be fully supported by the Kemper dealer channel,” he added. “Kemper will also integrate the full product portfolio into our sales, service and parts processes to offer world-class service to forage customers around the world.”

The current German Scherer importer, Tobias Häußer and Team, as well as the Italian importer, Agri Parts, which have been importing Scherer products for several years, will be integrated into the Kemper distribution network.

“It’s a very logical step for Scherer to offer our products outside of North America with the full support of the Kemper organisation,” the president of Scherer Inc, Bob Scherer, said. “We’re excited about the opportunity to work with Kemper in bringing our popular kernel processors available to these market sectors.”

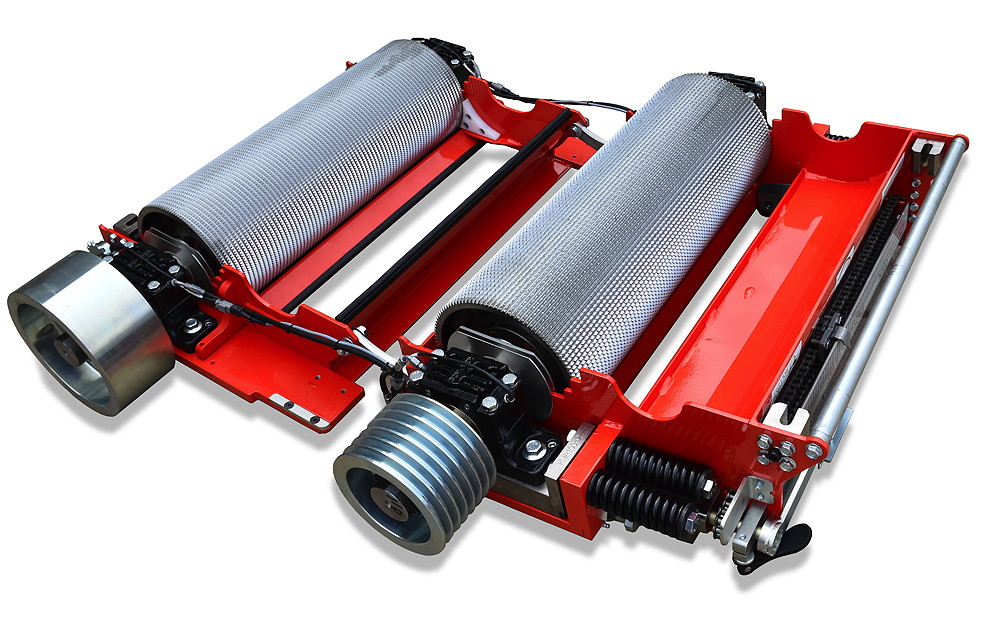

Scherer will produce the new processors according to Kemper design specifications. All components are manufactured in metric dimensions for Kemper and are subject to strict quality controls. The processors are sold in the Kemper brand color under the product name ProfiCracker.

The Kemper ProfiCracker is characterized by robust components such as rolls, shafts and bearings. The special TwinCut surface of the rolls ensures perfect kernel processing even at long lengths of cut. The bearings are continuously lubricated with an oil mist and thus run cooler and have a significantly longer lifespan. Another special feature is temperature measurement at the bearings, which allows continuous monitoring of the bearing function and warns the operator of high temperatures that indicate a possible failure.

Preventive repairs can be scheduled and, as a result, major damage and unwanted downtime in the field can be avoided. The patented hinge open design allows for easy access and servicing of the processor. The processor can be quickly opened making it easy to change the rolls.

In addition to the new ProfiCracker, Kemper will also supply replacement rolls for Claas crackers and Krone conditioners.

“We want to deliver all the requirements for excellent kernel processing while at the same time providing a significantly longer roll lifespan,” Mr Wigger said. “We’re also in discussion with other SPFH manufacturers about a possible collaboration.”

Processor rolls for current Claas and Krone forage harvesters will be available for sale on a limited basis for the 2019 harvest season. Kemper ProfiCrackers will be officially available for the 2020 season, however, a limited number of forage harvesters will be equipped with the new Kemper ProfiCrackers for the 2019 season.

For more information visit: www.kemper-stadtlohn.de.