That may seem a strange question, but as far as MAN’s TGS 18.500 is concerned, the answer is “when it’s a tractor”. Thanks to EU homologation rules, the buyers of this new agricultural-spec machine have the choice of how to register their purchase. Choose truck and they get a machine that has a 90km/hr top speed, but needs a driver with an HGV licence (for on-road use anyway) who needs to follow HGV driving rules; but, opt to register it as an agricultural tractor and just about anyone with a car driving licence can drive it at up 44t on the road, although the maximum speed will be limited to 60km/hr.

MAN has been building these agricultural-spec trucks for a few years now, but prior to Agritechnica 2017 they’d had a relatively low profile. Now, however, it feels it’s time to shout about these versatile machines. This is because there are now more transport tasks than ever for agricultural businesses to fulfill, and thanks to their high payload, low fuel consumption and high driving speed, trucks are gaining ground in the transportation chain between farm, field and warehouse. MAN claims that the price of the trucks – the 500hp TGS 18.500 costs about £130,000 in agricultural spec (about £40,000 more than the road-spec machine) – makes them more cost-effective than a similarly powered conventional tractor.

With this in mind, the MAN TGS is now available kitted out as an agricultural truck and featuring all-wheel drive, fifth-wheel coupling, agricultural trailer coupling and support, load-sensing hydraulic system and wide, soil-friendly agricultural tyres. Its ability to operate in the field, on the road and in further processing applications is where MAN agricultural trucks are really able to demonstrate their high level of efficiency. They offer distinct advantages in the transportation chain compared to other vehicle types, due to their high payload of 38t or 40t, lower fuel consumption and the higher speeds typical of trucks. What’s more, established semi-trailer combinations often enjoy greater acceptance among other road users than tractors with bulky, multi-axle trailers do.

Contractors are paying more and more attention to the efficiency and total cost of ownership of their fleet, while the public are concerned with the issue of environmental friendliness in the transportation chain. The increasing prevalence of biogas plants is ensuring increased transport volumes for the delivery of corn, grass and grain silage, as well as the movement of fermentation substrate across great distances. Transportation applications in particular are where trucks that have been adapted to meet the needs of the agricultural industry really show their strengths. This is something that has come to MAN’s attention with the increase in demand for adapted vehicle concepts.

The two-axle MAN TGS 18.500 4×4 BLS tractor impresses with its wide range of equipment specifically for use in the agricultural industry. It cxomes with permanent all-wheel drive, and for maximum traction, the driver can apply the differential locks in the longitudinal and then in the transverse direction using just one rotary switch. The all-wheel drive really comes into its own when combined with the soil-friendly agricultural tyres, as they allow the vehicle to leave the country lanes and move onto grasslands or fields.

The tyres are able to meet the various requirements placed on them: the low level of pressure they exert on the ground means they look after country lanes and productive land, their V-profile takes care of traction, and they are still able to manage high transport speeds on surfaced roads. If the standard truck width of 2.5m is to be maintained, 445/65 front tyres and 600/50 individual rear tyres are fitted to the axles, but if wider vehicles are permitted, the MAN TGS can run on 580/65R22.5 tyres at the front and 750/45R26.5 tyres at the back.

In the high design height, the driver can comfortably climb into the MAN cab using the four steps. The interior colours of “sand” or dark-grey “urban concrete” convey a user-friendly appearance. To provide a view of the load, windows have been incorporated into the rear wall. Alternatively – and often providing a more practical option – the images captured by two externally mounted cameras can be played on the seven-inch display of the new MAN infotainment system, enabling the driver to monitor the load and the area around the rear of the vehicle.

On the outside, the M cab impresses with functional accessories: grilles on the rugged, three-piece steel bumper protect the headlights. A step on the left mudguard with a long handrail on the roof makes it easier to see into the tipper and cross over to the semitrailer. Additional headlights illuminate the area around the vehicle and rotating beacons warn other road users. The attachment of a snow-plough mounting plate, with associated elevated headlights and indicators, enables contractors to make economical use of the vehicle in the winter season too. Behind the cab, the exhaust pipe is located on the right and tilted upwards to reduce the exhaust gases released in the vicinity of the vehicle and to prevent dust from being swirled up on the ground.

The six-cylinder, in-line engine from the MAN D26 Common Rail series has a capacity of 12.4 litres and delivers 500hp at 1,400rpm in the Euro 6 emission standard. Its maximum torque is 2,500Nm at 930 to 1,400 rpm. This engine series is also available with an output of 420hp and 460hp. The engine is coupled with the automated MAN TipMatic 12 gearbox. With its SmartShifting function, the driver is able to change gear particularly quickly depending on the driving situation in order to minimise the interruption to traction.

The “Offroad” gearbox software provided for all-wheel vehicles and which is activated by turning the gear selector switch is specially adapted for journeys over difficult terrain. It prevents drivers from skipping gears as well as indicating modified shifting times and higher shifting speeds to prevent interruption to drive traction. As a result, a typical truck speed of max. 89km/hr is possible even with a full payload – provided this is permitted in accordance with traffic regulations. At low and medium speeds in particular – as are common with MAN agricultural trucks – the wear-free MAN PriTader really demonstrates its brake force.

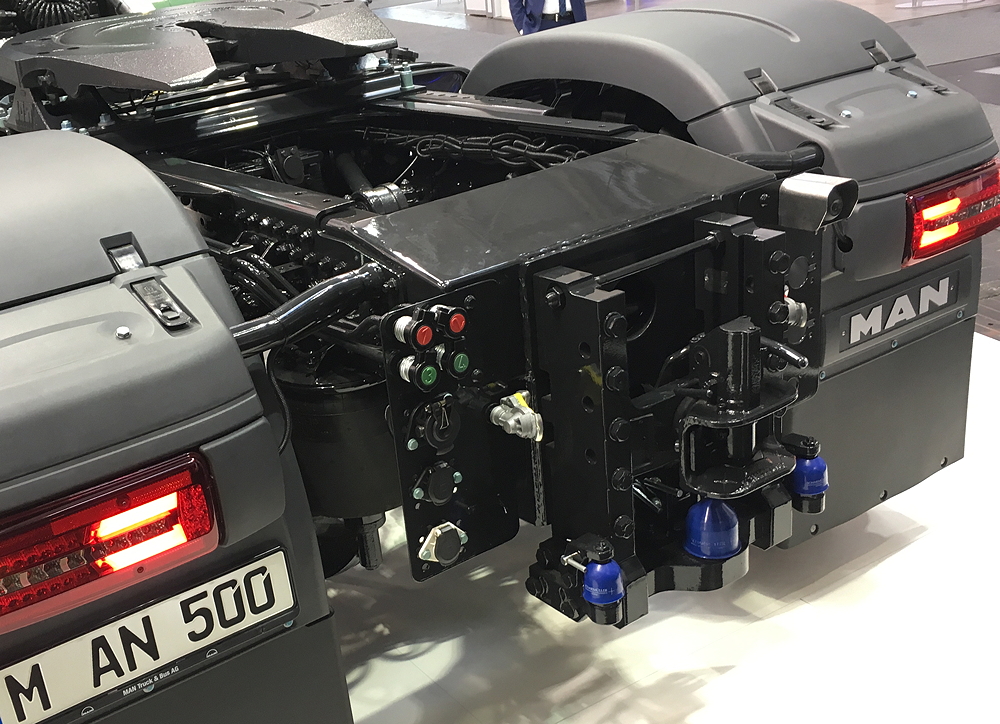

In terms of industry-specific equipment, MAN can also install a trailer coupling support in addition to the fifth-wheel coupling at the end of the frame. This is comprised of a bar coupling with a 38mm bolt and an 80mm ball coupling. It also includes two 50mm steering balls to pull agricultural trailers with forced steering. This mechanism allows the trailer to cleanly follow the path of the tractor vehicle when cornering. The installed load-sensing hydraulic system regulates the output and pressure as required. This means that the full hydraulic output is only provided when required and that fuel is saved, as the hydraulic pump does not have to permanently operate at full capacity to supply the hydraulic system with high pressure.

Alternatively to the two-axle semi-trailer tractor, the MAN TGS agricultural truck is available as a two-, three- or four-axle chassis with a drive ranging from 4×2 to 8×8 to allow various bodies such as grass silage trailers, push-off trailers, lime and fertiliser spreaders or slurry tanks to be mounted. Although this vehicle concept has the edge over the semitrailer combination in terms of its offroad properties, it is restricted with respect to its payload as well as being at a disadvantage in terms of its suitability for universal use and the extent to which it can be used economically all year round.

MAN TGS 18.500 4×4 specification:

| Type | MAN TGS 18.500 4×4 agricultural tractor with permanent all-wheel drive |

| Wheelbase | 3,900mm |

| Suspension | Front axle leaf-spring suspension Rear axle air suspension |

| Engine | 12,419cc, six-cylinder D26 Common Rail in-line engine, Euro 6 emission standard |

| Output | 500hp at 1,800rpm |

| Torque | 2,500Nm at 930-1,400rpm |

| Gearbox | MAN TipMatic 12 28 OD with offroad gearbox software |

| Rear axle | Planetary axle |

| Speed | 1.5-89km/hr |

| Permitted gross weight | 18,000kg |

| Permitted gross train weight | 40,000kg (technically 44,000kg) |

| Tyres | Front axle 445/65R22.5 Rear axle 600/50R22.5 |

For more information visit: www.truck.man.eu.