From the launch of the first Quadrant 1200 large square baler in 1988, Claas has led the way in the development of high-capacity large square balers. For 2017, this development continues with the launch of three completely new Quadrant baler models – the 5300, 5200 and 4200.

At the core of these new models is the redevelopment of Claas’ oldest patented product – the knotter. The first Claas knotter was patented in 1921, and with more than one million units now having been produced, Claas is still the only baler manufacturer to design and manufacture its own knotters.

In addition to the new high-capacity knotters, in order to further increase output and bale density, this new design of Quadrant baler also features heavier-duty drive systems, longer bale chambers and the new patented Claas Automatic Pressure Control (APC) system.

Standard on the Quadrant 5300/5200 and optional on the Quadrant 4200, APC takes high density baler performance to a new level, by ensuring that bale weight is maintained by automatically monitoring the knotters and the stress on the drive system.

Having entered both the required bale density and the quality of the baling string being used into the ISObus terminal, by monitoring sensors recording the deflection of the main beam and knotter tension on three of the knotters, APC will automatically maintain the target chamber pressure. This ensures that a uniform bale weight is maintained regardless of variations in crop quality.

As an option on the Quadrant 4200 and standard on the Quadrant 5300/5200, Knotter Control System (KCS) is also available where sensors are fitted to all six knotters. With KCS, stress on each of the knotters is monitored to detect any broken strings or a missed knot. This will then result in an alarm on the control terminal to alert the driver.

Producing a bale measuring 70cm x 120cm, the new Quadrant 5200 and 4200 replace the current Quadrant 3200 and 2200 models. The larger Quadrant 5300 produces a bale measuring 90cm x 120cm and replaces the Quadrant 3300.

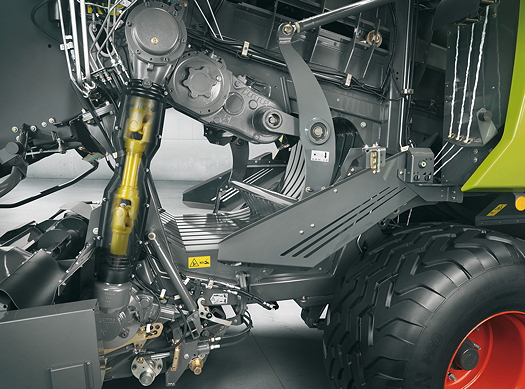

At the front, all three new models have a hydraulically suspended 2.35m-wide pick-up, fitted with a double roller crop press and Power Feeding System (PFS) auger as standard.

Claas is the first manufacturer to also offer the option of hydraulic drive to the pick-up reel, top crop press roller and the PFS auger. By being able to vary the pick-up speed from between 200 to 260 rpm, hydraulic drive allows the operator to match the speed of the pick-up to the crop, using a higher speed for small swaths for example or reducing the speed to minimise damage in crops such as Lucerne or hay. The hydraulic drive also allows the PFS and crop press to be reversed in the event of a blockage.

As previously, all three new models are available with either the Roto Feed or the 25-knife Roto Cut system. On the Quadrant 5300/5200, where even shorter chop lengths are required, these can be specified with either the Fine Cut rotor, where up to 51 blades can be engaged, or the Special Cut unit, which has 90 knives.

All three models feature a pre-chamber ahead of the main chamber. On the Quadrant 4200, the packing tines operate on a three phase cycle, driven by an oil-immersed gearbox and clutch drive system with automatic overload protection. On the Quadrant 5300/5200, there is electro-hydraulic control of the packing tines to provide optimum bale density and shape in varying crop conditions.

On all three Quadrants, in order to achieve even greater bale density and higher overall output, the bale chamber has been further strengthened and the length increased by up to 15 per cent. On the Quadrant 5200 and 4200, the chamber is fitted with three pressure rams, while there are six on the Quadrant 5300.

On the Quadrant 5200, ram frequency has been increased to 56 strokes/minute and on all models the ram, connecting rods and bearings have all been strengthened.

The knotter system fitted to all three models features a new bill hook, string guide finger and string clamping plate and disc design, which creates a single, improved shape of knot with longer ends for greater “hold’” in all baling conditions with no string waste.

To ensure the knotters stay clean, all three new Quadrants are fitted with a hydraulically powered Turbo Fan system, similar to that used for the Lexion Jet Stream system. New active oscillating diffusers direct the air, which travels at 140km/hr, across both the front but also the sides of each knotter, ensuring they are kept clean at all times.

For ease of maintenance, instead of being bolted down each knotter assembly can now be swivelled upwards and for when working at night, both the string box and needles can be fitted with LED lighting.

All three Quadrant models are Isobus compliant. The Quadrant 5300/5200 are controlled using the Claas Communicator colour terminal and the Quadrant 4200 uses the Operator terminal, with the option of the Communicator. All three can also be controlled using the Easy On-Board app using an iPad or via any Isobus-compatible terminal.

2017 Claas Quadrant range

| Quadrant 5300 | Quadrant 5200 | Quadrant 4200 | |

| Bale size | 120cm x 90cm | 120cm x 70cm | 120cm x 70cm |

| PU/PFS Hydraulic Drive | Optional | Optional | Optional |

| Bale chamber length (cm) | 381 (+11%) | 381 (+11%) | 345 (+15%) |

| Packer Clutch (Nm) | 9500 (+12%) | 8400 (+29%) | |

| Ram frequency (strokes/min) | 46 | 56 (+10%) | 51 |

| APC/KCS | Std / Std | Std / Std | Opt / Opt |

For more information visit: www.claas.co.uk.