Claas has led the way in corn cracking technology for forage harvesters since it developed the first corn-cracking system for the Jaguar back in the late 1980s, when the ability to crack maize kernels on the forager to improve digestibility and increase yields or weight gain was seen as a major step forward.

At Lamma 2016, Claas will be displaying a completely new crop processor, the Multi Crop Cracker (MCC) Shredlage, that provides another major step forward in crop processing technology and has been proven to increase milk yield by up to 2.0 litres a cow, so boosting revenue, and to enable output from home-grown forage to be maximised without the need for bought-in concentrates.

The new MCC Shredlage crop processor is an innovative processing technology for conditioning long-cut maize using the Claas Jaguar forage harvester. The Shredlage process, for which Claas has acquired the license, was developed in the US, where it has already been used successfully by dairy producers for a number of years.

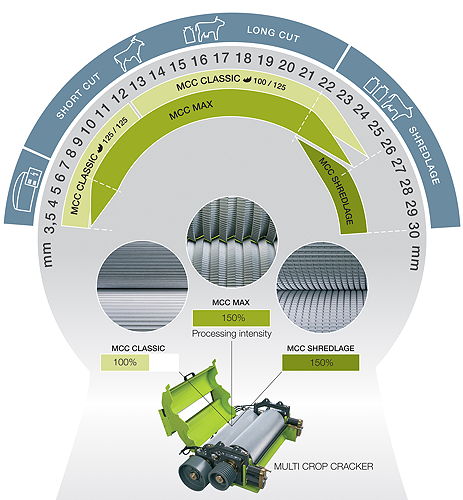

Shredlage involves chopping the maize to a long chop length of 26-30mm. The crucial part of the process is the subsequent conditioning using the MCC Shredlage cracker technology.

The two LorenCut rollers have 110 and 145 teeth and there is a 50 per cent speed difference between the two. The unique aspect of the rollers is that they also have a counter-rotating spiral groove, so that as the crop passes through the rollers, it’s also pulled apart by the sideways movement of the teeth, so that the cob pieces are fully broken down and the kernels crushed to break them open completely. As a result, the stalk material is shredded very effectively in the longitudinal direction and the bark is peeled off by the special roller structure.

The intensive shredding of the material significantly increases the surface area of the chopped crop, that results in much improved bacterial fermentation in the clamp and subsequently during digestion in the rumen of the cow.

Studies by the US University of Wisconsin have found that Shredlage significantly increases the structural suitability of maize silage for the rumen, while also improving the availability of starch from all parts of the plant. This resulted in an increase in daily milk production from the herds covered by the study of up to 2.0 lit/cow. Furthermore, the rumen-friendly structure of the silage also improved the health of the herds.

The results of the study correspond to the experiences of dairy farmers in the USA and Germany, who are already feeding long-cut maize silage to their animals. They also report a slight increase in silage intake, a flatter lactation curve and calmer animals. None of the farms involved in the study experienced any problems during the ensiling process of the longer maize crops.

In addition to the new MCC Shredlage processor, Claas will also have on display the latest MCC Max rollers, that are designed for use in chop lengths from 7mm to 22mm.

Instead of the conventional sawtooth profile, the two rollers utilise 15 sawtooth rings with a 30 per cent speed difference between the two. As the crop passes through the rings it’s not only crushed, but also sheared, ensuring that the kernels are more intensively conditioned and the stalk material is shredded.

As with the new Shredlage rollers, this provides a greater surface area to that digestible starch is increased, which will benefit both livestock farmers, but also operators of AD plants. It will also benefit the operator as it will allow them to meet the needs of a wider range of customers, without needing to change the corn cracker on the forager.

The new MCC Shredlage and MCC Max rollers are the latest addition to the Claas MCC modular concept. The MCC system is based on a single Crop Cracker housing in which the range of different MCC Classic, MCC Max and MCC Shredlage cracker rollers can be quickly and easily inserted and used.

By only needing to change the rollers for different crops of chop lengths, instead of the whole housing, this provides the operator with far greater flexibility and reduced downtime.

For more information visit: www.claas.co.uk.