Austria’s Bauer Group has acquired Silage & Gulle-Technik (SGT), a specialist manufacturer of high-capacity slurry application systems, expanding its already comprehensive portfolio of waste handling and spreading solutions.

SGT has made a name for itself primarily with an innovative slurry-loading system and large-capacity tank for the Claas Xerion, converting this powerful tractor into a self-propelled slurry spreader.

With the integration of SGT into the Eckart slurry tanker production site in Germany, Bauer will meet rising demand for high-performance self-propelled applicators to spread slurry from cattle and pigs, and digestate from anaerobic digester plants.

Bauer Group managing partner Otto Roiss said the plan was to make use of the modern in-house plastics production capabilities at Eckart to manufacture the SGT tanks, and for Bauer to take on responsibility for product development, production and after-sales service.

“The previous owner of SGT, Christiaan Seegers, as well as key employees, will remain involved, with Mr Seegers focusing more intensively on sales activities and innovations,” he added. “With the industrial manufacturing resources and high-quality standards of the Bauer Group, we expect extensive synergies for the products of SGT.”

This latest acquisition by Bauer Group broadens a comprehensive product line that includes everything from the famous original hose coupling system to slurry mixers, pumps and separators, and the largest trailed tankers with unique polyester tank designs for reduced weight but no loss of durability.

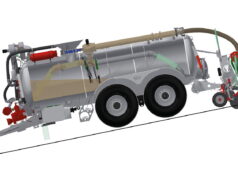

This material is being used for a new tank to fit the Claas Xerion 4000 Saddle Trac; it weighs 1,800kg less than the steel tank made for the previous forward control Xerion, yet at 16 cubic metres it holds an extra two cubic metres of slurry.

A new direct-mounting arrangement for the pump unit is available as an alternative to mounting it on the three-point linkage, a big advantage being that it weighs 900kg less. The new assembly also improves the operator’s forward visibility and can handle faster flow rates as there are only four bends in the pipework for slurry to negotiate instead of eight.

The assembly is available with a 10-inch or 12-inch remote docking system for filling, a 25cm stone-trap box and a 9,000- or 12,000-lit/min pump – the larger capacity option is offered for 24m to 36m slurry dribble booms.

For more information visit: www.bauer-at.com.