A new range of mobile holding tanks to aid with the spreading of digestate from biogas and anaerobic digestion plants has been launched by Northern Ireland-based manufacturer SlurryKat.

Responding to increased demand in the Nordic countries, the engineering division at SlurryKat, based in Waringstown, County Armagh, designed and built the Mobile Nurse Tank that acts as the master tank when spreading digestate with an umbilical slurry system.

Biogas plant operators and contractors expressed concerns that it was becoming a problem connecting haulage tankers to the umbilical system in the field. Spillage regularly occurred leaving an overdose on the field killing the crops in many cases.

SlurryKat chief executive Garth Cairns said that with the ever-increasing size of farms in Europe, and more and more biogas plants being constructed to produce renewable energy, there had never been a greater need for specialist slurry handling equipment and innovative solutions.

“In February 2015, we supplied a 3,000m SlurryKat umbilical system complete with 15m dribble bar to a biogas plant,” he said. “While the client was extremely happy with the performance of the SlurryKat umbilical system, they faced the challenge of their land being up to 40km away from the biogas plants.

“They were using tri-axle articulated road trucks to haul the digestate to the roadside of these fields and manually hooking a transfer hose between the truck and the umbilical system pump. This method encountered huge problems as the contractors found it a messy operation every time the hose was removed from the truck.

“Other problems were found when stopping the dribble bar in the field between each load. This stoppage created an overdose at that particular point in the growing crop, which led to the crop being damaged and in some instances killed off and left the fields looking very unpleasant.”

Mr Cairns added that following discussions with the owners of the biogas plant, he suggested that the company manufacture a large holding tank, which the umbilical system could be connected to.

“This system allows the trucks to bring the digestate to the roadside and discharge their load into the tank without affecting the operation of the umbilical system and, most importantly, no stoppages during the spreading process,” he said.

“The tank acts as a buffer, with the level in it rising and falling as the trucks discharge their load into it. Results have shown that the system allows for continuous spreading for hours and is considered a great technical advance in slurry handling management.”

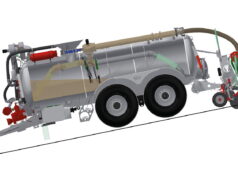

The tanks are constructed with a full frame monocoque construction with press formed side panels for added strength. They run on a specialised floating bogie axle system that can be raised and lowered from the safety of the tractor cab.

SlurryKat can build tanks to various sizes including 40, 60, 80, 100, 120 and 150 cubic metres. They have level indicators front and rear, with a top access hatch with external and internal ladders. All tanks also have a venting system with front and rear discharge/fill ports with sump system.

For safety reasons, each tank has a load protection system that prevents the tank to be lifted up to the wheels unless it’s completely empty as the tank is not designed to be moved with liquid inside.

Fitted with a commercial hydraulic lifting braked axle, the tanks run on 385/65R22.5 road tyres. All tanks are fitted with a LED lighting system.

For more information visit: www.slurrykat.com.