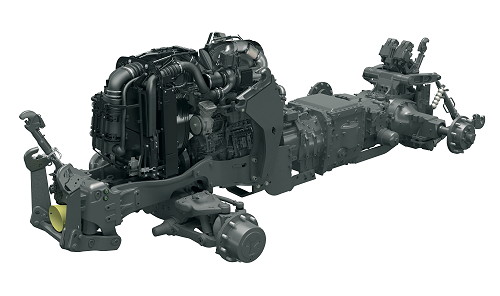

Following the introduction of the new Arion 600 and 500 last year, Claas has extended the range with the introduction of a new CMatic version, driven by a Claas-designed and built infinitely variable transmission.

The new CMatic transmission option will be available on all Arion 600 and 500 models. This means that Claas will now be able to offer an infinitely variable transmission option on all its tractors from the 145hp Arion 530 through to the 530hp Xerion 5000, which gives Claas the broadest range of CVT tractors on the market.

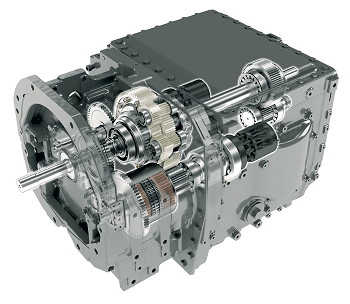

The new Arion CMatic models are all fitted with the new EQ200 transmission, which has been designed and built by Claas Industrietechnik, based at Paderborn.

As part of the development programme, Claas Power Systems assessed the suitability of various infinitely variable transmissions and how they performed, but found none that provided the high-performance characteristics that the company demanded. The decision was therefore made for Claas Industrietechnik to develop a new infinitely variable transmission specifically for the Arion range that would provide the performance characteristics required.

Claas Industrietechnik has been designing and manufacturing drive technology systems for nearly 50 years, so has long experience in the development of drive components, such as the Terra Trac units used on combine harvesters, electronics and hydraulics. Aside from manufacturing components used within Claas products, since 1975 the division has also supplied components to a wide range of agricultural and other off-road machinery manufacturers, in addition to automotive manufacturers such as Volvo and Mercedes Benz.

The new Claas EQ200 is based around two multi-plate clutches, a stepped planetary transmission and two wide-angle hydrostatic units from Danfoss Power Solutions. It’s the intelligent interconnection between the mechanical transmission and the hydrostatic units that give the EQ200 its unique characteristics.

As the tractor accelerates, the two clutch shafts gradually adjust their speed and eventually align at the moment when the transmission automatically changes from the lower to the higher speed ratio. As it changes to the higher speed ratio, the characteristics of the two hydrostatic pumps change, with the unit that was pumping changing function to being a motor, and the unit that was the motor becoming a pump.

This unique switch provides a completely seamless automatic change of range and avoids the need to manually change range. The driver doesn’t notice any change in drive ratio as they accelerate, giving them the ability to go from 0-50km/hr without any interruption in tractive power, combined with high, constant efficiency at any speed.

The new EQ200 transmission is the result of a £34 million investment by Claas and demonstrates the company’s commitment to the future development of the Claas tractor range. The transmission has involved over 80,000 hours of development work, with more than 17,000 hours of testing on a newly developed test rig and a further 15,000 hours of validation on the road and in the field.

In common with all other Claas tractors in the CMatic range, all Arion CMatic models feature Cebis and are controlled using the latest CMotion control unit that fits in the palm of the hand.

The operator has the option of three transmission modes that can be selected and set-up using Cebis. Using Automotive, acceleration is controlled using the foot throttle. The engine and transmission are automatically controlled for optimum fuel economy and when going downhill, the CMotion control can be pulled back to provide engine braking. In CMotion mode, the CMotion control is used to control the speed and the engine and transmission are automatically controlled, making this ideal for where a precise ground speed needs to be maintained. In Manual mode, the engine speed can be controlled using either the foot throttle or the CMotion control, while the transmission ratios can be changed manually using the CMotion, independent of engine speed.

The operator also has the option to set and save up to three cruise control speeds in both forward and reverse, and using Cebis they have the ability to alter the engine droop under load over a range from 5-40 per cent in one per cent increments.

A particular aim for the new EQ200 transmission for the Arion range was that it should provide a constant high efficiency across a wide range of engine speeds. The result is a flexible infinitely variable transmission that will ensure optimum power transfer to the ground. At the same time, it will provide a further reduction in fuel consumption from what is already the most fuel efficient range on the market, where the Arion 650 came out top in a recent DLG PowerMix test of 135-225hp Stage IIIB tractors, consuming just 273g/kWh.

For more information visit: www.claas.co.uk.