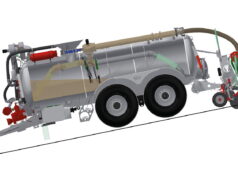

Hi-Spec Engineering has introduced a new version of the Xcel 1250 rear–discharge spreader for 2013 as part of its ongoing product development programme. The latest machine builds on the well–proven features of the spreader it replaces.

The Xcel 1250 is unique in that it uses a rotary chain and flail system to achieve a good break up of material, which is then spread using a pair of spinning discs. This has the benefit that in the event of a solid object, such as a lump of concrete, being encountered, this will pass through without causing any damage to the spreader, unlike a spreader fitted with vertical beater bars where there is the potential for costly damage to the rotors or bearings.

The new Xcel 1250 spreader has a solids capacity of 12t and a loading height of just 2.5m, and now features a new curved side panel design that provides an increased internal volume for greater capacity. This new design also has the advantage that it reduces the risk of material bridging.

To carry material to the slurry door at the rear of the spreader, the new Xcel 1250 is fitted with marine–type double floor chains that are suitable for use with a wide range of solid or liquid, sludge or very dry chicken manure. To keep downtime to a minimum, the chain can now be quickly tensioned manually and the hydraulic system has also been simplified.

As previously, material for spreading is initially broken-up by a patented and well–proven chain flail and spinning disc system. The heavy-duty marine grade chains are attached to a horizontal rotor and have a 10-tonne breaking capacity. Each of the chains is fitted with a Hardox steel flail to effectively break-up even the densest of manure. Hardox hard-wearing plate is also now used in all the critical wear zones throughout the spreading system for added durability, reliability and minimal downtime.

|

| The new Hi-Spec Xcel 1250 can spread a 12t load in 3-5 minutes. |

From the flail rotor, the broken-up material falls onto two hydraulically driven 960mm diameter spreading discs. Both discs have shear–bolt protection and are fitted with two spreading vanes. For lighter, dry material such as chicken litter or pellets, six-vane discs are available as an option. Depending on material, the twin rotors give an even spreading width from 16m to more than 20m and enable a full 12t load to be spread in about 3-5 minutes.

As part of its standard specification, the new Xcel 1250 is fitted with a wide–angle PTO, driving a 200hp rated gearbox, and the spreader’s main transmission system is protected by an over-run clutch and shear bolts.

To ensure that compaction and rutting is kept to a minimum, the Xcel 1250 is carried on 580/70R36 tyres with hydraulic braking, and it’s also fitted with high–visibility LED lighting with protective covers.

For more information visit: www.hispec.net.