Challenger’s new TerraGator 845 (TG845), which made its debut at Agritechnica 2011, is a completely new specialist self-propelled applicator that is packed with the latest technology and unique features.

The new four-wheeler is powered by an advanced Agco Sisu Power engine that is equipped with Selective Catalytic Reduction (SCR) technology and generates 400hp. Improving efficiency and easing operation of the unit is the TechStar continuously variable transmission (CVT). This extremely robust unit is well-proven in more than 150,000 farm machines at work today, including the TerraGator 8333 – the world’s first applicator to benefit from CVT technology.

The TG845, which is designed and built in Challenger’s European hub at Grubbenworst in The Netherlands, is a product of unrivalled application expertise and engineering experience. It’s a purpose-built application machine that offers contractors, operators and their customers a huge number of unique benefits.

This industry-leading CVT gearbox is significantly more efficient than many other competitive self-propelled machines that use powershift or hydrostatic designs and is able to transmit full engine power at any speed from 0-40km/hr. The maximum road speed can be achieved at an economical 1,700rpm.

The TechStar CVT has a range of automatic operating modes, controlled by a foot pedal or a hand lever, as well as the Power Direction lever. Mounted on the left-hand side of the dashboard, this lever provides seamless forward and reverse shuttling, an active standstill (declutch) and also changes the speed in both directions by simply pushing the lever.

Power Management provides an intelligent electronic link to the engine and works in existing pedal and lever modes. It automatically optimises the engine speed across the full engine rev/speed range to maintain the set forward speed. This increases output and cuts fuel consumption.

The new TG845 uses a new six-cylinder, 400hp Agco Sisu Power engine with a capacity of 8.4 litres. To meet Stage 3B emissions rules, the engine is equipped with SCR that processes the exhaust gases using AdBlue and a new diesel oxidation catalyser (DOC). This aftertreatment process enables engineers to set the engine characteristics for peak power and economy.

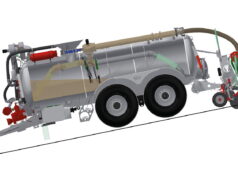

The TG845’s new strong, rear single-beam chassis design provides optimal weight distribution on the front and rear axles. This ensures there is more ground contact area from each of the large flotation four tyres, which increases traction while reducing compaction and wheelslip.

The Dog-Walk option ensures all wheels run over the ground in individual tracks. This spreads the vehicle’s weight more evenly over the ground and, because two wheels never run in the same path, it cuts the risk of creating ruts, which further protects the soil and the crop. The articulation point design ensures implements are always pulled in a straight line, without the need for a steering rear linkage. The steered rear Dog-Walk axle also makes the TG845 agile on the headland, minimising manoeuvring needed to get to the next pass.

Access to the spacious cab is via wide steps and platform, through a front-opening door. Inside operators are cosseted in the pressurised environment with Surround-Flow, climate control air-conditioning. There is superb visibility through the 5.5 square metre glass area and for added comfort there is the optional Semi-Active seat suspension. A new exhaust silencer design reduces noise.

|

| Challenger’s new TerraGator 845 develops 400hp from its Agco Sisu Power engine. |

The 10-inch touch-screen, Isobus compliant Falcon VT terminal is standard on the TG845 and operates with both liquid and dry applications. This comprehensive system provides full variable-rate control and mapping and uses buttons and a rotary dial to select functions and scroll through menus.

The system monitors forward speed by highly accurate and reliable radar and adjusts the flow of material, either liquid or solids, to automatically match the pre-set or variable-application rates. Via the task-controller functionality it’s easy to transfer and load application prescription data, create coverage maps and export this data via an SD-Datacard slot.

Addititional operator assistance is provided by the optional factory-fitted GPS auto-steer system. The AgCommand telemetry system is another option, which improves fleet management, machine monitoring and security as well and enhances record-keeping with detailed job reports.

Challenger’s exclusive Nutrient Management System (NMS) holds the key to fully exploiting the fertiliser value of liquid and dry manures as well as treated bio-solids. On top of cutting fertiliser costs, this accuracy of control will also help farms and businesses comply with ever stricter application and use restrictions and regulations.

The NMS system can be used with both liquid and solid (dry) materials and is operated through the Falcon VT terminal. Essentially, this electronic system monitors the vehicle’s forward speed and automatically adjusts the flow of material, either liquid or solids, to match the pre-set application rates. It works in a similar way to an electronically-operated sprayer or fertiliser spreader controller.

The new TerraGator TG 845 is equipped with either 15 cubic metre or 18 cubic metre capacity light and durable tanks, with liquid pumped via a robust 9.0 cubic metres/min positive displacement pump, which is hydraulically powered through a direct-drive gearbox. An on-board weighing system is available to provide accurate rate control with dry products being applied by the DNMS spreader.

The optional Superload system speeds filling time and increases overall workrates, employing a separate centrifugal pump, which after it has been charged by the positive displacement pump, produces a 12.5 cubic metre/min output.

The TG845 is equipped with a strong, Category 3, three-point linkage and is ideally-suited to work with mounted injectors, providing multiple settings of power down, lift and float with integral suspension for use with heavy implements and to adapt to various soil and crop conditions.