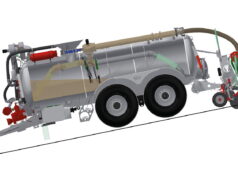

Hi-Spec Engineering used Grassland & Muck 2011 to launch its new XCEL 1250 rear-discharge spreader which uses flails in place of vertical rotors for spreading.

It’s one of life’s great mysteries how solid objects, such as concrete blocks, large stones or fencing posts, always seem to end up hiding in muck heaps, and the damage they can cause to the vertical rotors and bearings of a rear discharge spreader can be both costly and time consuming.

To overcome this, Hi-Spec Engineering has created the XCEL 1250 spreader that utilises a rotary chain and flail system, similar to a side-discharge machine, to achieve good break-up of the material for spreading.

The XCEL spreader has a solids capacity of 12t, or liquids capacity of 11.5 cubic metres. It has a loading height of just 2.5 m and is suitable for use with a tractor of at least 100hp.

The robust main body of the XCEL spreader is manufactured using 5mm plate steel for the floor and 4mm plate on the sides, which is then shot blasted prior to painting to ensure a durable finish. The drive to the main spreading components is through heavy-duty driveshafts powered by 200hp-capacity gearboxes.

The sides of the spreader are tapered for easy loading and the contents of the spreader is carried to the rear of the machine on a twin chain and slat floor, which is automatically tensioned and has a breaking capacity of 80t. The floor is powered by a variable hydraulic motor with overload protection, which is controlled from the cab. The rear slurry door is operated by a slave and master cylinder system to guarantee it stays level at all times for an even spread.

|

| Depending on the material, the twin rotors give an even spreading width of between 16-20m and enable a full 12t load to be spread in about 3-5 minutes. |

For spreading, in place of the vertical beaters found on other machines, the XCEL 1250 features a horizontal rotor that carries 24 heavy-duty marine grade chains that have a 10t breaking capacity. These in turn are fitted with Hardox steel flails to effectively break-up even the most dense of manure.

By using chains in place of solid rotors, this means that the contents of the spreader can still be effectively broken-up and shredded, but in the event of a solid object being encountered, this will pass through without causing any damage to the spreader.

From the flail rotor, the broken-up material falls onto two hydraulically driven 960mm diameter spreading discs. Both the discs have shear-bolt protection and are fitted with two spreading vanes. For lighter, dry material, such as chicken litter or pellets, six-vane discs are available as an option.

Depending on the material, the twin rotors give an even spreading width of between 16-20m and enable a full 12t load to be spread in about 3-5 minutes.

The standard specification includes a central greasing point and automatic chain oiler and tensioner, plus protective covers for the rear lights and indicators, and a slurry door height indicator. The XCEL 1250 is also fitted as standard with 580/70R38 tyres, with hydraulic brakes, to ensure that compaction and rutting is kept to a minimum.

For further information visit: www.hispec.net.