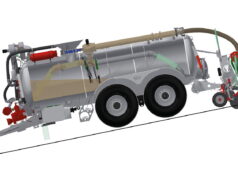

The first Joskin slurry tankers fitted with centrifugal pumps have left the company’s factory as the Belgian manufacturer, which first specialised in vacuum systems, has extended its range with volumetric pumps.

The pumps, which are used only to empty the tankers, have flows ranging from 6,000-10,000 lit/min. The new concept is ideal for farm businesses with slurry pits equipped with filling pumps, or where gravity filling is possible.

The new tankers are filled through an upper hydraulic trap door, or through a rear or side inlet. The centrifugal pump has a three-way valve that allows it to work in closed circuit to mix the slurry. The capacity of the new pumps also means they can be used to feed a rear spreading tool with a large application width.

First designed for the Nordic countries, this new tanker concept can be easily transferred to holdings already using gravity filling, and the system is fully compatible with the range of application system options available from Joskin. A range of different capacities is also available.

For more information visit: www.joskin.be.