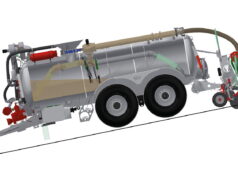

Shelbourne Reynolds has updated its range of side-delivery manure spreaders with the introduction of two new models to the Powerspread range. Both are designed to handle both slurry and solid manures.

The Powerspread Pro 3000 is the larger of the two new models and has a capacity of about 15t. The concept behind its development was to boost capacity and increase discharge rates to bring it in line with the output expected from similarly sized rear-discharge spreaders.

While the Pro 3000 is aimed primarily at contractors and large-scale livestock farmers, the more conservative Powerspread 2400 has a capacity of about 11t and is ideally suited for use by more average-sized livestock units.

Both models employ a large-diameter horizontal auger to convey material to the centrally positioned rotor which then powers it out to the right of the machine to create an even, 20m wide spread pattern. The use of more vertical rather than sloping sides used in previous models, along with an agitator unit eliminates any tendency for material to bridge above the auger as the spreader empties.

The rotor, which turns at 750rpm, has an upward rotation and uses the specially strengthened edge of the exit door as a shear bar; material is reduced in size as it leaves the machine and creates an even spread pattern. The door itself has a hydraulically operated slide so that application rates can be controlled from the tractor cab.

Aware that extraneous material such as lengths of wood and large stones, can find their way into a spreader and cause blockages, Shelbourne has built in a raft of protection and clearance systems for the two new spreaders. For starters, the main drive from the PTO has a shear-bolt protection and two further shear-bolts provide overload protection for the rotor and auger drive – both of which employ simple chain-and-sprocket drive systems. The paddles are attached to the rotor by a single bolt and, as a result, when an obstacle is encountered, rotate backwards to prevent damage.

Should the system experience a blockage, access to the machine is made easy by raising the exit door slide to its full extent and, for the first time, by being able to hydraulically lower the rotor to below floor level so the maximum accessible area becomes available. A reverse-drive facility is also fitted as standard enabling the operator to reverse the central feed auger in the event of a blockage.

For maintenance, a bank of greasing points is placed conveniently at the front of the spreader and supplies grease to all the main bearings. Chain tensioners ensure the two drive chains always run correctly.

Both the Pro 3000 and 2400 models require very little power to operate; the brunt of the power is required to handle the weight of the fully loaded spreaders. As such, Shelbourne Reynolds recommends a minimum of 120hp for the larger 3000 spreader and 100hp for the smaller 2400 model.

Running gear comprises large-diameter tyres on a single axle with an option for tandem axles. Options extend to air brakes instead of hydraulic brakes and, for those needing to know precise application rates, weigh cells can be fitted.

In the Pro 3000 and 2400, Shelbourne Reynolds has created two spreaders that offer a high degree of versatility in their ability to handle a full range of manure types along with capacities to suit both large and smaller scale requirements.

The proof of the design is in the way manure is spread, and the speed at which it can be spread. On this score, the even pattern created is exemplary and the speed of operation more than equals that of similarly sized rear-discharge machines.

For more information visit: www.shelbourne.com.