German biogas plant constructor Planet Biogastechnik has received its first order to build an agricultural biogas plant in the UK.

German biogas plant constructor Planet Biogastechnik has received its first order to build an agricultural biogas plant in the UK.

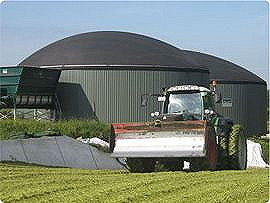

The clients are two farmers in Herefordshire that are going to build a 190kW biogas plant, with construction due to begin in spring 2010.

The proposed plant will consist of one digester and one digestate tank, and is designed to utilise approximately 3,300t of maize silage, 1,000 cubic metres of cattle slurry and 600t of chicken manure every year.

Planet’s scope of supply includes everything from planning application support services to construction, commissioning and biological consultancy through the Planet laboratory.

“We are very happy, that the owners of the broiler farm approached Planet for a comprehensive consultancy, in order to check out the potential of available biomass and to design a tailor-made biogas plant”, the company’s project manager for the UK, Stephan Hoffmann, said. “The farmers were looking for a profitable way of recycling the chicken manure from their farm on one hand, and saving energy costs for heating the broiler houses on the other hand. Our biological analysis of the chicken dung with sawdust available on the farm has offered a proper basis for a stable fermentation process.

The farm, with a capacity of more than 90,000 broilers per turnover, is going to establish a modular biogas concept, which optimally fits into the daily farm operation. The surplus heat from the CHP unit will be used to heat the three broiler houses located adjacent to the plant.

“For our clients it is very important to have the possibility to stay flexible, even in a long term distance”, Mr Hoffmann added. “Therefore our biogas plant is designed as a modular system. The digestate tank, for example, is equipped with a gas tight roof, insulation beneath the base and heating pipes in the base and walls, so it can easily be upgraded into a fully functional secondary digester.”

Commissioning of the plant is planned for early autumn 2010.

For more information visit: www.planet-biogas.co.uk.