Farmers visiting the Dairy Event and Livestock Show in September will have their first opportunity to inspect a unique system designed to reduce the cost of providing a safe and comfortable bedding material for cattle.

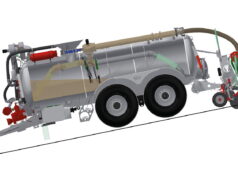

The Bedding Recovery Unit (BRU) being launched at the event by farm-waste handling specialist Spreadwise has been developed by Fan Separator GmbH, an affiliate of the Austrian ecotechnology company Bauer.

Spreadwise recently installed and commissioned the first such unit to be used anywhere in Europe. It separates undigested fibres from slurry then dries and sanitises them to produce an economical source of bedding that also has a beneficial impact on a farm’s slurry storage requirements.

“The BRU is an innovative, cost-effective and environmentally friendly system that not only has the potential to reduce bedding costs but also to reduce a farm’s carbon footprint,” the managing director of Spreadwise, Fred Percival, said. “It produces a dry and absorbent material available fresh every day from a process that kills potentially harmful bacteria and also reduces slurry storage capacity needs by as much as 20%.”

The system works by separating the liquid and fibre content of slurry then treating the larger undigested fibres in a patented aerobic process that dries them while eliminating any harmful bacteria. This process requires no external heat source, so the bedding material is produced with very low energy consumption.

“The material produced by the BRU is safe and provides cows with a comfortable environment that reduces the risk of injury and encourages improved milk yield,” the manager of the Bauer affiliate Fan, Klaus Ferk, added. “And since the process runs automatically, it needs little intervention or management other than routine daily checks and maintenance.”

Investment in a Fan BRU will also be recouped through cost-savings in home-produced or bought-in bedding materials and streamlined storage and application of slurry.

Spreadwise and Bauer staff are currently monitoring the performance of the first installation on a Cheshire dairy farm and plan to release details of installation and running costs and pre- and post-installation bacterial counts in due course.

For more information visit: www.bauer-at.com.