The new OxyGenerator Super 6 grassland aerator – that can also spread slurry and dirty water on grassland – has mimicked the original models in winning a leading award.

The new OxyGenerator Super 6 grassland aerator – that can also spread slurry and dirty water on grassland – has mimicked the original models in winning a leading award.

The OxyGenerator Super 6 was placed runner-up in the New Equipment Awards at the 2009 Royal Show, the same venue where the original model received the RASE Silver Medal in 2007.

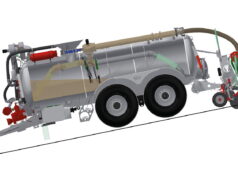

The new model fits in at the top end of the range, which was previously available up to 5m width, and will require a 150hp tractor. The added ability to spread slurry and dirty water will make the machine a much more flexible tool use in grassland management.

The machine folds to 3m for road transport. It weighs 1,500kg, with the capacity to add 1,200kg of ballast by locating a set of 200-litre water barrels in the top frame – the same system that helps ensure the original design of OxyGenerator maintains excellent penetration. Price of the standard model is £9,450.

It features four 1.5m long solid steel shafts on which the aerating blades are fitted using a robust double-flanged mounting. Blades are made from durable 11mm thick boron steel and penetrate to 180mm, a depth at which they do a highly effective job of shattering the shallow compaction caused by machinery or livestock treading.

Axles can be set in one of three positions – straight, or at either three or five degrees offset – with wider angles increasing the degree of shatter. When set in the angled positions the blades leave a significant sized slit that assists quick absorption of applied slurry, which will improve the utilisation of the nutrients it contains.

The trailing hose supplying the slurry/dirty water is located into a housing on top of the machine’s frame. Slurry spreading is aided by the use of low trajectory splash plates, while the entire machine is made from galvanised steel to withstand corrosion.

“The OxyGenerator is a core part of Glenside’s grassland management system, which aims to maximise forage production from the farm’s natural resources, especially its soils, slurry and farmyard manure,” said the company’s technical director, Robert McCoull.

“It can remove compaction resulting from livestock treading or mechanical field operations, and when linked with the company’s advice on appropriate soil and grassland management, can reduce the need for applied fertilisers, while simultaneously raising the nutritional quality of both grazing and conserved forage.

“With the added ability to spread and incorporate slurry and dirty water, the machines offer both the output and flexibility required by modern livestock farms.

“Customers regularly report that the original OxyGenerator could help save them 50kg/ha of nitrogen – a significant financial saving given current fertiliser prices – and we expect this new model to improve that, as well as helping prevent leaching and nitrogen losses, which should help livestock farmers meet their Cross Compliance obligations.”

For more information visit: www.glensidegroup.com.